Twin Screw Pumps

Roto Gear Timed Dual – Flow Twin Screw Pumps is dependent on the rotation of two screw spindles in closed compartment. Wherein, a predefined clearance is maintained between the screw spindles as well as between the outside diameter of the screw spindles and the bore of the casing/liner in which the screw spindles are located. Each half of the screw spindles is left-handed and right-handed. Thus, when the spindles start rotating, driven by a pair of timing-gears located at the end of the screw spindles, the liquid is drawn towards the end of the screw spindles and entrapped between the bore of the pumping compartment as well as the flanks of the screws and is then propelled axially from both the ends towards the centre. Such a dual flow nullifies the axial thrust completely thereby enabling the screw spindles to remain in a state of hydraulic balance. Roto’s unique double profile of the screw spindles contributes to a higher volumetric efficiency, thus an improved overall efficiency.

These pumps widely confirm to API 676, 3rd edition and are ATEX and CE certified.

Twin Screw Pumping Principle

The working principle of Roto Gear Timed Dual – Flow Twin Screw Pumps is dependent on the rotation of two screw spindles in closed compartment. Wherein, a predefined clearance is maintained between the screw spindles as well as between the outside diameter of the screw spindles and the bore of the casing/liner in which the screw spindles are located. Each half of the screw spindles is left-handed and right-handed. Thus, when the spindles start rotating, driven by a pair of timing-gears located at the end of the screw spindles, the liquid is drawn towards the end of the screw spindles and entrapped between the bore of the pumping compartment as well as the flanks of the screws and is then propelled axially from both the ends towards the centre. Such a dual flow nullifies the axial thrust completely thereby enabling the screw spindles to remain in a state of hydraulic balance. Roto’s unique double profile of the screw spindles contributes to a higher volumetric efficiency, thus an improved overall efficiency.

- Long and trouble-free service life due to absence of metal to metal contact between the pumping elements. It can even run dry for limited period of time.

- No axial thrust Dual flow of liquid in opposite direction balances axial thrust.

- Higher volumetric efficiency due to special double profile of screw flanks.

- High cavitation free suction lift due to low NPSH (R).

- Wider conformity to API 676, 2nd edition.

- Self-priming and capable of handling entrapped air/vapour/gas due to positive displacement action and being inherently self-priming.

- Uniform metered flow Being a positive displacement pump, head developed is independent of speed and capacity is approximately proportional to speed.

- Capable of handling wide variety of fluids lubricating/non-lubricating as well as aggressive liquids can be handled due to choice of different designs and material of construction.

- Safe to operate has in-built relief valve, designed to bypass up to 100% capacity.

Range

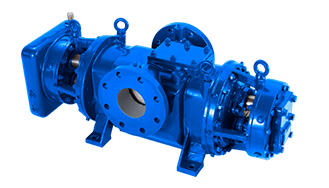

HORIZONTAL INTERNAL BEARING

Horizontal Internal Bearing Twin Screw Pumps are selected where the fluids are clean and have lubricating properties. These pumps are designed with internal bearings which get lubricated by the pumping media itself. The suction and discharge ports are in-line.

The mechanical seals are provided as standard scope of supply. Gland packing option can also be offered as per application requirement. These pumps are fitted with relief valves and are suitable for 100% bypass. Also, these pumps are available in standard foot mounted configuration with sump heating arrangement as an option.

Internal Bearing RI Series

Capacity: up to 1000 m3/hr

Pressure: up to 40 bar

These pumps are designed for clean and lubricating media. The pumps are fitted with the bearings inside and the bearings are lubricated with the pumping media itself. They are available in standard foot mounted configuration with sump heating arrangement as an option. It is built in safety relief valve, designed for 100% bypass.

CASING:

• Cast Iron, • Cast Steel, • Fabricated Steel • Fabricated Stainless Steel

LINER:

• Case Steel, • Stainless Steel

SCREWS:

• Alloy Steel • Stainless Steel, • Hardened Steel

TIMING GEARS:

• Hardened Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex

SCREW SURFACE COATING:

• Hard Chrome Plating

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Paper Industry

- Sugar Industry

- Oil and Gas Industry

- Edible Oil Industry

- Marine Industry

- Power Plant Industry

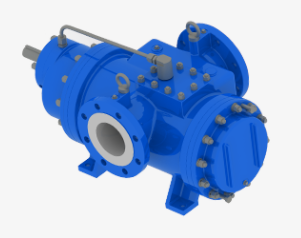

HORIZONTAL EXTERNAL BEARING

Horizontal External Bearing Twin Screw Pumps are suitable for handling fluids with different characteristics at different temperatures (up to 3500C / 6600F) .

These pumps are available in standard foot mounted & center-lined mounted configuration with or without steam jacketing arrangement.

Due to external bearing mounted design, the media does not come in contact with the bearings and thus ensures longer service life even with the corrosive or abrasive fluids. These pumps are built with relief valves, designed for 100% bypass. The suction and discharge ports are in-line.

The mechanical seals are provided as standard. Gland packing option can also be offered as per application requirement. Also, API 682 type mechanical seals can be offered.

External Bearing RE Pump

Capacities up to 1000 m3/hr

Pressures up to 40 bar

CASING:

• Cast Iron, • Cast Steel, • Fabricated Steel • Fabricated Stainless Steel

LINER:

• Case Steel, • Stainless Steel

SCREWS:

• Alloy Steel • Stainless Steel, • Hardened Steel

TIMING GEARS:

• Hardened Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex

SCREW SURFACE COATING:

• Hard Chrome Plating

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Paper Industry

- Sugar Industry

- Oil and Gas Industry

- Edible Oil Industry

- Marine Industry

- Power Plant Industry

- Pharma Industry

- Fertilizers Industry

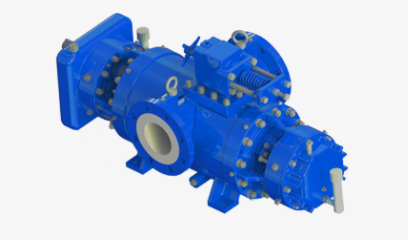

VERTICAL TWIN SCREW PUMP

Roto’s Vertical Twin Screw Pumps are available in both external & internal bearing configurations. These pumps are designed to suit the applications where space is a constraint. These pumps can handle fluids with high temperatures up to 3500C / 6600F with or without steam jacketing. Electrical/steam tracing arrangement is available as an option.

The mechanical seals are provided as standard. Gland packing option can also be offered as per application requirement. Also, API 682 type seals can be offered.

These pumps are built with relief valves, designed for 100% bypass. The suction & discharge ports are in-line.

Vertical Internal / External Bearing RV series

Capacities up to 1500 m3/hr

Pressures up to 40 bar

CASING:

• Cast Iron, • Cast Steel, • Fabricated Steel • Fabricated Stainless Steel

LINER:

• Case Steel, • Stainless Steel

SCREWS:

• Alloy Steel • Stainless Steel, • Hardened Steel

TIMING GEARS:

• Hardened Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex

SCREW SURFACE COATING:

• Hard Chrome Plating

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Paper Industry

- Sugar Industry

- Oil and Gas Industry

- Edible Oil Industry

- Marine Industry

- Power Plant Industry

- Pharma Industry

- Fertilizers Industry