The construction guarantees the optimal position of the laminated seal against the seat. Jamming due to thermal expansion is eliminated.

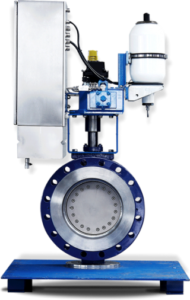

TORQUE TRANSMISSION USING KEYS

The disc is keyed to the shaft not pinned, providing balanced torque transmission and eliminating the danger of pins shearing off.

IDEAL LAMINATION AND DISC DESIGN

The strong disc with its eliptical supporting surface offers the best fixing of the lamination. Bubble tightness is given as a result of the special machining of the lamination.

SUPPORTING BEARING BUSHINGS

The optimal position of the bearing reduces the risk of the shaft bending. This guarantees bi-directional tightness at maximum differental pressure.