Helical Turbine Meters

Helical Turbine Meters

HTM Series

The Helical Turbine Meter for liquid Hydrocarbons Custody Transfer Applications.

The HTM series of turbine meters is designed for high accuracy volume measurement of crude oils and other liquid hydrocarbons.

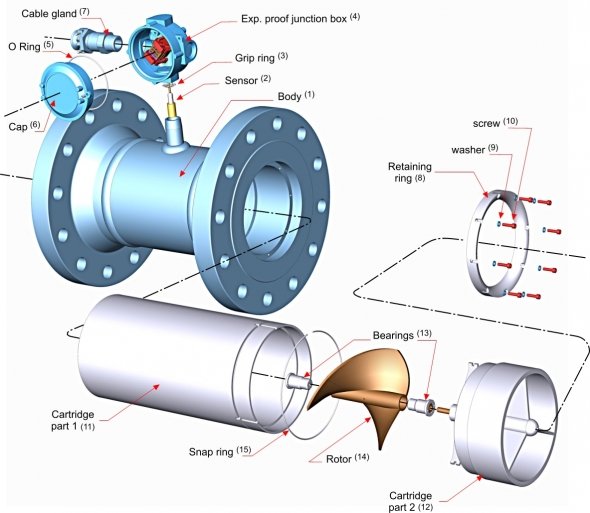

The turbine meter consists of a dual-helical blade rotor (14) that rotates as liquid passes through the meter. The rotation of the rotor is proportional to the volume of liquid flowing through the meter. The rotor is fitted with small magnets in each blade that make the sensor(s) (2) switch every time a rotor blade passes. Two diametrically opposed sensors are normally fitted. The rotor is located in a pressure-balanced measuring chamber (11, 12) that is maintained in the flow meter body by means of a screwed retaining ring (8).

Every pulse generated by the sensor corresponds to a volume value or pulse weight.

The nominal number of pulses per volume unit (K-Factor) depends on the meter size and is accurately determined at flow meter calibration stage (laboratory proving or field proving).

M&T helical turbine meters are preferred for their high robustness and performance on liquid hydrocarbons custody transfer such as Export loading terminals, FPSOs, pipelines, separators.

Cross-plates supporting the HTM rotors are welded to the measuring chamber two part system. This ensures a perfect bearing set alignment. The friction is therefore reduced for best measurement repeatability.

Unlike other turbine assembly systems, the HTM measuring chamber can be removed and then re-installed without need of recalibration. The tungsten carbide grade for the bearings is carefully selected to minimize erosion – even in harsh conditions such as sand content in hydrocarbons. The shaft is lubricated by means of small ducts embedded in the bearing pockets, preventing the accumulation of particles or paraffin that could increase friction.

Benefits

- Low to high viscosity design for single or multi-viscosity metering applications with stable meter factors

- Superior linearity and repeatability

- Counting starts from close to zero flow

- Helical rotor protected against severe corrosion

- Helical rotor rounded front profile for meter performance stability when fibres or contaminants are present in crude oil

- Tungsten carbide 3 parts special design bearings for long life duration and debris self cleaning

- Stainless Steel interchangeable measurement cartridge for easy site maintenance and downtime reduction

- Special materials available (Duplex, Hastelloy, Inconel)

- Low pressure drop