High Pressure Progressive Cavity Pump

One of the most dynamic designs for driving the flow of variety of liquids, Progressive Cavity Pumps can be customized to efficiently handle liquids with different viscosity levels and chemical properties. The Progressive Cavity Pumps comprise of a precision mechanized single external helix metallic rotor and double internal helix elastomer stator. As the rotor turns within stators, the cavity progresses from suction to discharge along with fluid.

Pumping Principle

Progressive Cavity Pumping Principle

The pumping element comprises of a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions. As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid.

Positive Displacement

Because of single rotating element, progressive cavities are generated which deliver a uniform, metered and non-pulsating flow. The developed head is independent of the rotational speed, where as the capacity is proportionate to the speed.

Self priming

Inherently self-priming, the pumps can work on snore and do not require a foot valve.

Non-Clogging

Can handle solid in suspension or media containing a high percentage of solids.

Low NPSH Requirement

Suction lift capabilities of up to 9.5mWc and effective in high vacuum conditions.

Low Internal Velocity

Minimum degradation of shear-sensitive media, and can also handle highly viscous materials having pseudo-plastic characteristics.

Reversible

Due to the reversible rotation capabilities, Progressive Cavity Pumps can perform with equal efficiency in either direction.

Silent Running

Rotors turn inside a resilient stator and thus generate little noise.

Separate Bearing Housing

Fluids can be pumped without no contamination.

- Paper Industry

- Sugar Industry

- Agriculture Industry

- Oil and Gas Industry

- Paint, Varnish and Ink Industry

- Mining Industry

- Chemical Industry

- Food Industry

- Explosives Industry

- Man Made Fibers Industry

- Ceramic Industry

- Edible Oil Industry

- Cosmetics and Herbal Industry

- Toiletries Industry

- Dye Stuff Industry

- Marine Industry

- Waste Water Treatment Industry

- Pharma Industry

- Steel Industry

- Textile Industry

- Power Plant Industry

- Bio Gas Industry

Range

Standard PC Pump

Roto Xtra Value Progressive Cavity Pumps are designed to pump ‘tough – to – handle’ fluids with ease in varied industries. The construction of these pumps is based on the modular concept and comprises of next generation pumping elements i.e. Rotor, Stator, Solid Shaft and Double Sealed Cardan Universal Joints for improved performance and longer service life.

These pumps are available in bare shaft and close coupled configuration. Selected pump sizes are available with 6 stages and 8 stages.. Options also available with different material grades and shaft sealing.

Capacity: up to 500 m3/hr

Pressure: up to 6 bar

These Heavy Duty cost effective pumps use the extended Rotor, Stator Geometry and results in lower rubbing velocities which are ideal for various applications.

Capacity: up to 250 m3/hr

Pressure: up to 48 bar

These heavy duty pumps are designed for continuous or intermittent duty and are suitable to perform efficiently even for the most difficult fluid handling applications in various industries.

WETTABLE HOUSING COMPONENTS:

• Cast Iron • Cast Stainless Steel • Fabricated Steel • Fabricated Stainless Steel

STATOR:

• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR:

• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless Steel

COUPLING ROD:

• Alloy Steel • Stainless Steel

SHAFT:

• Alloy Steel • Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

ROTOR SURFACE COATINGS:

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

PROTECTIVE COATINGS:

• Rubber Lining • Epoxy Coatings

Dry Running Protection Device:

To prevent the stator damage due to dry running, specially developed temperature sensor is screwed into the stator wall to monitor the operating temperature. If by any chance the pump runs dry, the stator temperature would increase. Roto DRP would switch off the pump at pre set temperature.

Pressure Switch:

To prevent the pump from damage due to over pressurization in the discharge as well as low pressures beyond the capability of the pump. This system trips the pump and protects the pump as well as the system.

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Paper Industry

- Sugar Industry

- Agriculture Industry

- Paint, Varnish and Ink Industry

- Mining Industry

- Chemical Industry

Small Capacity ‘RD’ Series Pumps (Standard Geometry)

| Size | D41 | D43 | D45 | D47 | D49 | D51 | D53 | D55 |

|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||

m3/hr | 0.11 | 0.3 | 0.6 | 1.6 | 3.5 | 6.5 | 9.5 | 17 |

GPM | 0.4 | 1.3 | 2.6 | 7 | 15 | 29 | 42 | 75 |

| Pressure | ||||||||

Bar | 24 | 48 | 24 | 24 | 24 | 12 | 12 | 6 |

PSI | 348 | 696 | 348 | 348 | 348 | 174 | 174 | 87 |

Medium to Large Capacity ‘RM’ series Pumps (Standard Geometry)

| Size | M50 | M52 | M54 | M56 | M58 | M60 | M62 | M64 | M66 | M69 | M72 | M73 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||||||

m3/hr | 4 | 8 | 14 | 18 | 26 | 31 | 55 | 78 | 95 | 150 | 200 | 250 |

GPM | 18 | 35 | 62 | 79 | 114 | 136 | 242 | 343 | 418 | 660 | 880 | 1100 |

| Pressure | ||||||||||||

Bar | 48 | 48 | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

PSI | 696 | 696 | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

Xtra Large Capacity ‘RL’ Series Pumps. (Extended Geometry)

| Size | L54 | 54M | L57 | 57M | L59 | 59M | 61M | L63 | 63M |

|---|---|---|---|---|---|---|---|---|---|

Capacity | |||||||||

m3/hr | 14 | 18 | 25 | 31 | 42 | 51 | 56 | 70 | 86 |

GPM | 62 | 79 | 110 | 136 | 185 | 224 | 246 | 308 | 380 |

Pressure | |||||||||

Bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

PSI | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 |

| Size | 65M | L67 | 67M | L71 | 69M | 71M | L75 | 73M | 76M |

|---|---|---|---|---|---|---|---|---|---|

Capacity | |||||||||

m3/hr | 114 | 116 | 152 | 195 | 212 | 272 | 345 | 352 | 420 |

GPM | 502 | 511 | 669 | 860 | 933 | 1198 | 1520 | 1550 | 1850 |

Pressure | |||||||||

Bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

PSI | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 |

Wide Throat PC Pump

Wide Throat type inlet allows gravity flow of highly viscous (plastico – Viscous) material on to the augur-on-coupling rod which pushes the substance to the pumping element. Wide Throat Pumps with the twin paddle bridge breaker arrangement at the top are designed for handling extremely difficult media with very high solid content and non – flowing properties.

Available in close coupled and bare shaft configuration. Custom designed hopper is also available on requirement. A variety of construction materials and shaft sealing options are also available.

Standard Hopper & Oversized Hopper

Capacity: up to 200 m3/hr

Pressure: up to 36 bar

WETTABLE HOUSING COMPONENTS:

• Cast Iron • Cast Stainless Steel • Fabricated Steel • Fabricated Stainless Steel

STATOR:

• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR:

• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless Steel

COUPLING ROD:

• Alloy Steel • Stainless Steel

SHAFT:

• Alloy Steel • Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

ROTOR SURFACE COATINGS:

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

PROTECTIVE COATINGS:

• Rubber Lining • Epoxy Coatings

Dry Running Protection Device:

To prevent the stator damage due to dry running, specially developed temperature sensor is screwed into the stator wall to monitor the operating temperature. If by any chance the pump runs dry, the stator temperature would increase. Roto DRP would switch off the pump at pre set temperature.

Pressure Switch:

To prevent the pump from damage due to over pressurization in the discharge as well as low pressures beyond the capability of the pump. This system trips the pump and protects the pump as well as the system.

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Paper Industry

- Sugar Industry

- Agriculture Industry

- Chemistry Industry

- Paint, Varnish and Ink Industry

- Mining Industry

- Textile Industry

- Cosmetics and Herbal Industry

- Waste Water Industry

- Bio Gas Industry

- Ceramics Industry

Wide Throat ‘WM’ Series Pumps (Standard Bucket)

| Size | W54 | W56 | W58 | W60 | W62 | W64 | W66 | W69 | W72 | W73 |

|---|---|---|---|---|---|---|---|---|---|---|

Capacity | ||||||||||

m3/hr | 7 | 12 | 16 | 28 | 35 | 47 | 57 | 90 | 120 | 150 |

GPM | 31 | 53 | 70 | 123 | 154 | 207 | 251 | 396 | 528 | 660 |

Pressure | ||||||||||

Bar | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

PSI | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

Wide Throat with bridge breaker ‘KM’ Series Pumps (Standard Bucket)

| Size | K54 | K56 | K58 | K60 | K62 | K64 | K66 | K69 | K72 | K73 |

|---|---|---|---|---|---|---|---|---|---|---|

Capacity | ||||||||||

m3/hr | 5 | 7 | 10 | 17 | 21 | 28 | 34 | 54 | 72 | 100 |

GPM | 22 | 31 | 44 | 75 | 92 | 123 | 150 | 238 | 317 | 440 |

Pressure | ||||||||||

Bar | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

PSI | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

Wide Throat ‘WM’ Series Pumps (Over Size Bucket)

| Size | W54 | W56 | W58 | W60 | W62 | W64 | W66 | W69 | W72 | W73 |

|---|---|---|---|---|---|---|---|---|---|---|

Capacity | ||||||||||

m3/hr | 7 | 12 | 16 | 28 | 35 | 47 | 57 | 90 | 120 | 150 |

GPM | 31 | 53 | 70 | 123 | 154 | 207 | 251 | 396 | 528 | 660 |

Pressure | ||||||||||

Bar | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

PSI | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

Wide Throat with bridge breaker ‘KM’ Series Pumps (Over Size Bucket)

| Size | K54 | K56 | K58 | K60 | K62 | K64 | K66 | K69 | K72 | K73 |

|---|---|---|---|---|---|---|---|---|---|---|

Capacity | ||||||||||

m3/hr | 5 | 7 | 10 | 17 | 21 | 28 | 34 | 54 | 72 | 100 |

GPM | 22 | 31 | 44 | 75 | 92 | 123 | 150 | 238 | 317 | 440 |

Pressure | ||||||||||

Bar | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

PSI | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

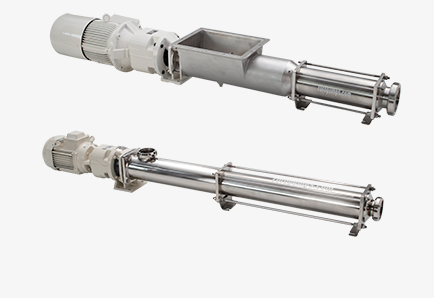

Dosing Pump

Dosing Pumps – The best choice for precise metering applications

These pumps are developed for low flow applications that demand high accuracies and repeatability with unique advantages of smooth and non-pulsating flow. These dosing pumps can handle clean and clear liquids.

The pump is ideal for either intermittent or continuous dosing duties. These dosing pumps can handle minimum flow as low as 0.68 LPH to 500 LPH & ensure proportionate dosing of media.

RJ Series Pump

Capacity: between 0.68 – 500 lph

Pressure: up to 24 bar

WETTABLE HOUSING COMPONENTS:

• Cast Stainless Steel

STATOR:

• Natural • Nitrile • High Nitrile • EPDM• Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR:

• Stainless Steel

COUPLING ROD:

• Stainless Steel

SHAFT:

• Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

ROTOR SURFACE COATINGS:

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

Dry Running Protection Device:

To prevent the stator damage due to dry running specially developed temperature sensor is screwed into the stator wall to monitor the operating temperature. Due to any reason if the pump runs dry, the stator temperature will increase. Roto DRP would switch off the pump at preset temperature.

Pressure Switch:

To prevent the pump from damage due to over pressurization in the discharge as well as low pressures beyond the capability of the pump. This system trips the pump and protects the pump as well as the system.

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Waste Water Treatment

- Pharma

- Cosmetics

- Chemical

- Mining

- Food

Dosing ‘RJ’ Series Pumps

| Size | RJ01 | RJ03 | RJ07 | RJ14 | RJ30 | RJ80L |

|---|---|---|---|---|---|---|

Capacity | ||||||

LPH | 7 | 17 | 42 | 84 | 166 | 460 |

GPM | 0.03 | 0.076 | 0.185 | 0.371 | 0.732 | 2.025 |

Pressure | ||||||

Bar | 24 | 24 | 24 | 24 | 24 | 6 |

PSI | 348 | 348 | 348 | 348 | 348 | 87 |

Food Pump

These Heavy Duty Semi-Hygienic Pumps are designed for handling food and beverages pumps industry applications. All metallic parts in contact with the medium being handled are fabricated in smooth finish stainless steel. These food pumps are provided with metal bonded aseptic food grade stator resistant to oil & fats. These pumps are standard with closed universal joints enabling it to handle fluids with low lubricating value like aerated or dematerialized water.

These food and beverage pumps are available in close coupled and bare shaft configurations. Sealing option is provided in hygienic quality gland packing or mechanical seal. These food grade pumps are also available with CIP port configuration. For highly viscous and non-flowable liquids, these pumps can be customized with wide throat configuration. Standard connections available in IDF, SMS & RJT.

DM Series Pump

Capacity: 86 m3/hr

Pressure: up to 24 bar

WETTABLE HOUSING COMPONENTS:

• Fabricated Stainless Steel

STATOR:

• Nitrile Black • Nitrile White • EPDM Black • EPDM White • Fluoroelastomer

ROTOR:

• Stainless Steel

COUPLING ROD:

• Stainless Steel

SHAFT:

• Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

Dry Running Protection Device:

To prevent the stator damage due to dry running, specially developed temperature sensor is screwed into the stator wall to monitor the operating temperature. Due to any reason if the pump runs dry, the stator temperature will increase. Roto DRP would switch off the pump at preset temperature.

Pressure Switch:

To prevent the pump from damage due to over pressurization in the discharge as well as low pressures beyond the capability of the pump. This system trips the pump and protects the pump as well as the system.

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Food

- Wine and Beverages

Food ‘DM’ Series Pumps (Standard Geometry)

| Size | DM51 | DM53 | DM54 | DM56 | DM58 | DM60 | DM62 |

|---|---|---|---|---|---|---|---|

Capacity | |||||||

m3/hr | 7 | 10 | 14 | 18 | 26 | 37 | 55 |

GPM | 31 | 44 | 62 | 80 | 115 | 163 | 242 |

Pressure | |||||||

Bar | 12 | 12 | 12 | 12 | 24 | 24 | 12 |

PSI | 174 | 174 | 174 | 174 | 348 | 348 | 174 |

Food ‘DM’ Series Pumps (Extended Geometry)

| Size | 54M | 57M | 59M | 61M | 63M |

|---|---|---|---|---|---|

Capacity | |||||

m3/hr | 18 | 31 | 51 | 63 | 86 |

GPM | 80 | 136 | 225 | 277 | 380 |

Pressure | |||||

Bar | 6 | 6 | 6 | 6 | 6 |

PSI | 87 | 87 | 87 | 87 | 87 |

Submerged / Vertical Pump

Roto Submerged Pumps are designed to operate with the pumping elements immersed in the media. These pumps are custom designed for varying column length to suite the sump depth. The strainer can be attached in suction port to prevent large solids entering the pump. Pumps are available in only close coupled configuration with variety of construction material and shaft sealing options. These pumps are compact and space saving.

Single Stage & Multi Stage Vertical Pumps

Capacity: up to 500 m3/hr

Pressure: up to 12 bar

WETTABLE HOUSING COMPONENTS:

• Fabricated Steel • Fabricated Stainless Steel

STATOR:

• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR:

• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless Steel

COUPLING ROD:

• Alloy Steel • Stainless Steel

SHAFT:

• Alloy Steel • Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

ROTOR SURFACE COATINGS:

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

PROTECTIVE COATINGS:

• Rubber Lining • Epoxy Coatings

Dry Running Protection Device:

To prevent the stator damage due to dry running, specially developed temperature sensor is screwed into the stator wall to monitor the operating temperature. Due to any reason if the pump runs dry, the stator temperature will increase. Roto DRP would switch off the pump at preset temperature.

Pressure Switch:

To prevent the pump from damage due to over pressurization in the discharge as well as low pressures beyond the capability of the pump. This system trips the pump and protects the pump as well as the system.

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

- Oil and Gas

- Power Plant

- Biogas

Vertical ‘VL’ Series Pumps (Standard Geometry)

| Size | D41 | D43 | D45 | D47 | D49 | D51 | D53 | D55 |

|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||

m3/hr | 0.11 | 0.3 | 0.6 | 1.6 | 3.5 | 6.5 | 9.5 | 17 |

GPM | 0.4 | 1.3 | 2.6 | 7 | 15 | 29 | 42 | 75 |

| Pressure | ||||||||

Bar | 24 | 48 | 24 | 24 | 24 | 12 | 12 | 6 |

PSI | 348 | 696 | 348 | 348 | 348 | 174 | 174 | 87 |

| Size | M50 | M52 | M54 | M56 | M58 | M60 | M62 | M64 | M66 | M69 | M72 | M73 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | |||||||||||||

m3/hr | 4 | 8 | 14 | 18 | 26 | 31 | 55 | 78 | 95 | 150 | 200 | 250 | |

GPM | 18 | 35 | 62 | 79 | 114 | 136 | 242 | 343 | 418 | 660 | 880 | 1100 | |

| Pressure | |||||||||||||

Bar | 48 | 48 | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 | |

PSI | 696 | 696 | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 | |

Vertical ‘VL’ Series Pumps (Extended Geometry)

| Size | M50 | M52 | M54 | M56 | M58 | M60 | M62 | M64 | M66 | M69 | M72 | M73 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||||||

m3/hr | 4 | 8 | 14 | 18 | 26 | 31 | 55 | 78 | 95 | 150 | 200 | 250 |

GPM | 18 | 35 | 62 | 79 | 114 | 136 | 242 | 343 | 418 | 660 | 880 | 1100 |

| Pressure | ||||||||||||

Bar | 48 | 48 | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

PSI | 696 | 696 | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

| Size | 65M | L67 | 67M | L71 | 69M | 71M | L75 | 73M | 76M | |

|---|---|---|---|---|---|---|---|---|---|---|

Capacity | ||||||||||

m3/hr | 114 | 116 | 152 | 195 | 212 | 272 | 345 | 352 | 420 | |

GPM | 502 | 511 | 669 | 860 | 933 | 1198 | 1520 | 1550 | 1850 | |

Pressure | ||||||||||

Bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

PSI | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | |

General Purpose Pumps

General Purpose pumps are designed for use where low flow transfer duties in domestic and wide range of industrial applications are required. These pumps have excellent suction lift capability up to 8 meters for water.. It is available in close coupled configurations and with standard IEC frame motors.

Capacity: up to 8 m3/hr

Pressure: up to 3 bar

Roto’s Little-Champ DC Pump range are compact, light weight and easy to maintain. 11,12 & 31 pump sizes are available with UV resistant Acetyl-co-polymer housing and 41 & 51 pump sizes are available with cast Iron housing.

Capacity: up to 2.8 m3/hr

Pressure: up to 5 bar

Roto’s Robust MC Pump range are widely used for general pumping and transfer duties. These pumps are available in 5 sizes with capacities ranging from 750 LPH to 2800 LPH and pressure up to 5 bar.

Capacity: upto 12 m3/hr

Pressure: upto 3.5 bar

These General purpose pumps are designed for transfer duties in light industrial applications.

DC Series

WETTABLE HOUSING COMPONENTS:

• UV Resistant acetate co-polymer housing for pump sizes DC 11 & DC 31

• C.I. Housing parts for pump sizes DC 41 & DC 51

STATOR:

• Natural, • Nitrile • High Nitrile • Fluoroelastomer

ROTOR:

• Stainless Steel

SHAFT:

• Stainless Steel

ROTOR SURFACE COATINGS:

• Hard Chrome Plating

MC Series

WETTABLE HOUSING COMPONENTS:

• Cast Iron

STATOR:

• Natural, • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer

ROTOR:

• Stainless Steel

SHAFT:

• Stainless Steel

ROTOR SURFACE COATINGS:

• Hard Chrome Plating

SC Series

WETTABLE HOUSING COMPONENTS:

• Ductile Iron • Cast Stainless Steel

STATOR:

• Natural, • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer

ROTOR:

• Stainless Steel

SHAFT:

• Stainless Steel

ROTOR SURFACE COATINGS:

• Hard Chrome Plating

DC Series

- Transfer and dosing of chemicals and alkalies

- Transfer duties in food processing, winery and vegetable oils

- Drainage of septic tanks

- Feeding to oily water separators

- Drawing water from wells, creeks or shallow bores

- Hosing down of cattle and stock sheds

- Automatic water pressure systems

- Berine injection

- Fiiding ponds and sprinkler systems

- Diesel transfer

- Hndling surfactants and detergents

MC Series

- Cellar drainage

- Septic tank/cess pit emptying

- Garden sprinkler systems/ irrigation

- Water supply/sampling form wells, streams and rivers

- Diesel

- Water based inks

- Vegetable oils

- Non-aggressive chemicals

SC Series

- Drainage of septic tanks

- Feeding to garden, sprinkler system

- Drawing water from wells, creeks or shallow bores

- Diesel transfer

- Feeding to oily water separators

Little Champ ‘DC’ Series Pumps (DC Series Pumps)

| Size | DC11 | DC12 | DC31 | DC41 | DC51 |

|---|---|---|---|---|---|

Capacity | |||||

m3/hr | 0.72 | 0.9 | 1.74 | 4 | 8 |

GPM | 3.17 | 3.96 | 7.66 | 17.6 | 35 |

Pressure | |||||

Bar | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

PSI | 40 | 40 | 40 | 40 | 40 |

Mini Range ‘MC’ Series Pumps (MC Series Pumps)

| Size | MCCS | MCCF | MCCG | MCCH | MCCL |

|---|---|---|---|---|---|

Capacity | |||||

LPH | 750 | 1150 | 1600 | 2800 | 3100 |

GPM | 3.3 | 5 | 7 | 12.3 | 13.65 |

Pressure | |||||

Bar | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

PSI | 50 | 50 | 50 | 50 | 50 |

Mini Range ‘SC’ Series Pumps (SC Series Pumps)

| Size | SC311 | SC321 | SC331 | SC441 |

|---|---|---|---|---|

Capacity | ||||

m3/hr | 0.45 | 1 | 22 | 3.5 |

GPM | 1.98 | 4.7 | 94 | 15 |

Pressure | ||||

Bar | 3.5 | 3.5 | 3.5 | 3.5 |

PSI | 50 | 50 | 50 | 50 |

Tirrana Agricultural Pump

Tirrana Agricultural Range

Capacity: 360 LPM

Pressure: 120 Meter

Built on heavy duty and proven platform. The Tirrana range of helical rotor pumps offer a peace of mind and best solutions to all types of surface water transfer duties.

Why Tirrana is your go to pump?

Ensuring Smooth flow of Water, Viscous, Abrasive & Shear Sensitive Media

Fair Pricing Policy for Pumps & Spares

Readily Available Pump and Spares Stock

Robust Distributor Network

24*7 Quick Service Support

Power Source

- Close Coupled with Electric Motor (240V or 415V)

- Petrol / Diesel Drive Options

Wettable Housing Parts: Cast Iron

Rotor: Stainless Steel – 410, Hard chrome plated

Stator: Natural, Nitrile

Shaft and Coupling Rod: Stainless Steel – 410**

* Above material options are standard for Tirrana Range, contact Roto for other material requirement

** With gland packing, shaft is hard chrome plated under gland area.

- Ideal for tank filling or stock watering from dams, creeks, wells and rivers.

- Can handle clean water, brown water, dirty water with sand, silt or algae.

- High Suction Lift Applications

- Viscous, Abrasive & Solid Laden Media

- High / Varying Discharge Pressures Applications

- Dirty / Salty Water

Inherently Self-Priming

Low NPSH Requirement

Exceptional Suction Lift Capabilities of up to 9.5 mwc

Effective in High Vacuum Conditions

Ideal for High Discharge Pressure Application

Provide Constant Flow at Varying Pressures

- Agriculture

- Mining

- Wastewater

- Food Processing