SUTO iTEC GmbH Thermal Flowmeters

Thermal Mass Flowmeter S 450

- For gas

- For compressed air

- Metal tube

The CS-iTEC flow sensor S 450 is based on the thermal mass flow principle. It measures volumetric standard flow over a wide measuring range and compressed air consumption. The result is pressure and temperature independent. S 450 flow / consumption sensor is designed specifically for harsh environments. The NEMA 4X enclosure with IP67 allows all-weather applications, All parts which come into contact with the measurement medium are made of stainless steel 316L. This allows applications in pharmaceutical and food industry, but also the measurement of corrosive and contaminated gas. Installations in explosive environment can be done through the optional ATEX approval. Various gases can be measured such as air, oxygen, argon, carbondioxyde, natural gas, hydrogen, methane, etc. Basically any gas mixture can be measured as long the mixing ratio and its components are known and constant.

Min.: 1,600,000 Pa (232.06 psi)

Max.: 4,000,000 Pa (580.15 psi)

23 °C (73 °F)

Min.: 0.2 m³/h (7.1 ft³/h)

Max.: 19,814.8 m³/h (699,753.1 ft³/h)

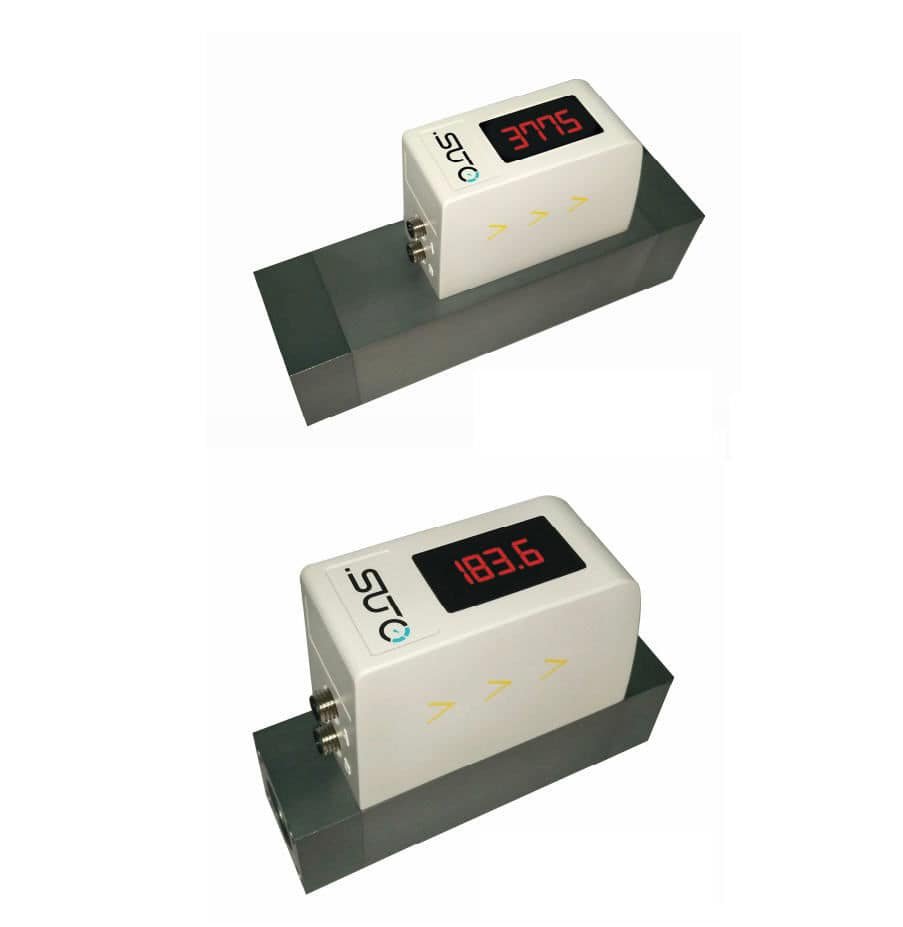

Thermal Mass Flowmeter S415 / S418

- For compressed air

- Digital

- Ultra-compact

The SUTO thermal mass flow meters S 415 and S 418 offer gas flow and consumption measurement at the point of use with various options. S 415 is the answer whenever economic is a major concern. S 418 is targeting those applications where accuracy, data logging and pressure measurement is required.Through the Bluetooth interface the user can use the SUTO App to check and edit the flow meter settings.

Min.: 0 bar (0 psi)

Max.: 10 bar (145.04 psi)

Min.: -30 °C (-22 °F)

Max.: 70 °C (158 °F)

Thermal Mass Flowmeter S 401

- For gas

- Digital

- 4-20 mA

The flow sensor is available in two measuring ranges S 401-S (standard range), S 401-M (max range) and S 401-H (high speed). The unit can be ordered with and without local display. The version with display shows the volumetric flow and the total compressed air consumption. Via the keyboard tube diameters and the consumption counter can be set. Various settings such as gas type, flow unit, reference standards, can be set ex factory or through our service kit. The service kit consists of a PC software and a interface box which connects the flow meter to the USB port of the PC. Every flow meter includes an analogue output (4…20mA) for flow and a pulse output for the consumption counter or MODBUS

Thermal Mass Flowmeter S 421

- For gas

- Compact

- 4-20 mA

The S 421 flow and consumption sensor covers a wide measuring range. With the high resolution and sampling rate a very fast and precise measurement is achieved. The installation is done through the selected measuring section, with R-thread or with flange connection. The sensors is able to save two calibration curves, due to this the sensor can be used in two different gases without any loss of accuracy. The optional color display is designed to show all measured values, at the same time it can be used to manage the sensor settings like pipe diameter, gas type or analog output scaling. The sensor offers two different signal output options. It can have a isolated analog and pulse output to read out the flow and the total consumption. Alternatively a MODBUS/RTU interface can be used to access all measured values via the digital interface. Various settings such as gas type, flow unit, reference standards, can be set ex factory, through our service kit or through the optional display. The service kit consists of a PC software and a interface box which connects the flow meter to the USB port of the PC.

Thermal Mass Flowmeter S 452

- For compressed air

- For gas

- Digital output

The CS-iTEC flow sensor S 452 is based on the thermal mass flow principle. It measures volumetric standard flow over a wide measuring range and compressed air consumption . The result is pressure and temperature independent. S 452 is designed specifically for harsh environments. The NEMA 4X enclosure with IP67 allows all-weather applications, All parts which come into contact with the measurement medium are made of stainless steel 316L. This allows applications in pharmaceutical and food industry, but also the measurement of corrosive and contaminated gas. Installations in explosive environment can be done through the optional ATEX approval. Various gases can be measured such as air, oxygen, argon, carbondioxyde, natural gas, hydrogen, methane, etc. Basically any gas mixture can be measured as long the mixing ratio and its components are known and constant.

Max.: 4,000,000 Pa (580.15 psi)

Min.: 1,600,000 Pa (232.06 psi)

23 °C (73 °F)

Max.: 47,880.4 m³/h (1,690,880.4 ft³/h)

Min.: 0.2 m³/h (7.1 ft³/h)