Vibration Data Collectors and Analyzers

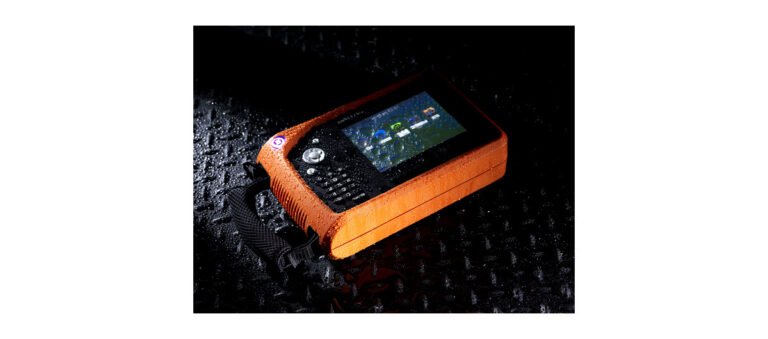

vPod Pro Smart Vibration Meter

The vPod Pro Smart Vibration Meter is designed for machine health monitoring and predictive maintenance.

• IP65-rated case with anti-drop rubber sleeve

• 3.5″ color screen

• Built-in 24G flash memory

• Route-based vibration data collector measures bearing condition and temperature at the same time

• Optional spectrum analysis function

• Buit-in camera for taking on-site photos as a note when storing data

● IP65 rated dustproof and waterproof case with anti-drop rubber sleeve

● Equipped with a 3.5″ color screen for intuitive and easy-to-understand operation interface

● Built-in 24G flash memory provides sufficient storage space

● Innovative sensor allows measurement of vibration values, bearing condition, and temperature at the same time

● Optional Spectrum Analysis Module and Route-based Vibration Data Collector Module

● A camera on the back allows you to add a photo taken on-site as a note when storing data

● Supports Bluetooth headset connection for listening to the vibration signal

● USB 2.0 and Wi-Fi transmission interface to transfer data to a PC.

The vPod Pro Smart Vibration Meter is designed for machine health monitoring and predictive maintenance.

• IP65-rated case with anti-drop rubber sleeve

• 3.5″ color screen

• Built-in 24G flash memory

• Route-based vibration data collector measures bearing condition and temperature at the same time

• Optional spectrum analysis function

• Buit-in camera for taking on-site photos as a note when storing data

• Supports Bluetooth headset connection for listening to the vibration signal

• USB 2.0 and Wi-Fi transmission interface

• Measure vibration signals in the frequency range of 1~8kHz

• High-strength magnetic base to secure the transmission of high-frequency signals

• Infrared temperature sensor

Detect low-frequency vibration of rotating equipment, such as

• Dynamic balance problems with the rotating parts

• Shaft misalignment

• Looseness

The vPod Pro Smart Vibration Meter’s built-in ISO 10816-3 vibration standard displays vibration severity in green, yellow, and red.

• Measures the bearing signal in the 1 kHz to 10 kHz bandwidth

• Implements the “true peak” value for detecting bearing damage

• Detects and tracks the bearing condition for early damage detection and predictive maintenance

• Detects bearing condition effectively on ultra-low speed machines

• Shows bearing condItions in green, yellow, and red background

Bluetooth headset connection

• The vPod Pro Smart Vibration Meter has a built-in feature that connects to Bluetooth headsets

• After each measurement, the user can automatically play 2~8 seconds of vibration signal through the Bluetooth headset

• Experienced users can use this auxiliary function to tell whether an equipment is abnormal or not

Camera function

• The vPod Pro Smart Vibration Meter has a built-in camera

• Can be attached to a live shot as a record while storing measurement data

• Photo linked to the measurement data and sent back to the PC-based iSee Predictive Maintenance Software

Spectrum analysis function (optional)

• Spectrum data is measured at the same time as a diagnostic vibration problem

• Select 1 kHz bandwidth of 1600 resolution lines or 10 kHz bandwidth of 6400 resolution lines

Route-based Vibration Data Collector Module (optional)

• Works with iSee Predictive Maintenance Software

• Measures basic vibration, bearing condition, temperature, and raw vibration signal

• Converts raw signal into a time waveform, two sets of spectrum analysis, envelope spectrum, and cepstrum

• Quickly track problematic measurement points, trend changes, diagnose problems and generate reports

VP5 Vibration Data Collector

Advanced Machinery Condition Monitoring and Root Cause Vibration Analysis

VP5 is Benstone’s state-of-the-art, 4-channel portable vibration data collector and analyzer.

• Large 6.4” color, VGA high-resolution touch screen

• Powered by WinCE operating system

• 24-bit sigma delta AD converters

• Up to 40 kHz maximum bandwidth

• High-speed DSP for real-time signal analysis

VP5 Vibration Data Collector

VP5 is a 4-channel portable vibration data collector and handheld vibration analyzer powered by Microsoft Windows CE and state-of-the-art DSP technology. VP5’s rugged housing is made from a high tech, dual-material injection process, consisting of hard ABS plastic (black) and soft TPR plastic (orange). VP5 also has rubber seals for IP65 protection in extreme weather and harsh environments. Equipped with VGA resolution color touch screen, VP5 brings you a state-of-the-art experience with in-field portable vibration analyzers.

● Data Collection and Recording

● Rotor Dynamic Balancing

● Computed Order Tracking

● Data Recorder

● Bump Test

● ODS test

• IP65-rated housing

• Rugged housing made by a dual injection molding process

• CE mark

• IEC 60068-2-34 vibration test

• IEC 60068-2-27 shock test

Route-Based Data Acquisition

Combined with the powerful computer-based iSee predictive maintenance software, the field-proven VP5 portable vibration data collector is your best choice for route-based data acquisition.

● Simultaneous tri-axial measurements (x,y,z axes) save hours in the field

● Measures bearing fault signal via true peak detection on a high-pass filtered time waveform

● Sensitive and accurate readings of early-stage of bearing damage allow the user to track bearing damage development via a trending analysis feature in iSee predictive maintenance software

● Envelope spectrum measurement for confirming bearing damage is a standard feature

● Temperature and other process parameter measurements are supported

Bump Test Module

VP5’s optional and powerful Bump Test Module allows you to measure a structure’s frequency response frequency (FRF), coherence, and cross power spectrum functions. This useful vibration analysis software module helps investigate the resonance of a machine, enact structural reinforcement and reduce the vibration levels of a machine running at its resonance zone. Test data can be imported to a 3rd party software, such as ME’Scope, for further modal analysis to derive its modal shapes, natural frequencies and damping values.

ODS Test module

VP5’s optional Operational Deflection Shape (ODS) module allows you to conduct a measurement on a running machine and measure its FRF, coherence, and cross power spectrum functions. With the reference vibration sensor connected to channel 1 and a triaxial vibration sensor connected to channels 2, 3, and 4, the VP5 vibration data collector saves you time in the field with real-time, 4-channel measurements. By importing the test data to a 3rd party software, like ME’Scope, you can easily derive the operational deflection shapes of your machines at certain running speeds and use this information for structural reinforcement.

Computed Order Tracking Module

The optional Computed Order Tracking module is designed to analyze the sound or vibration signals of varying-speed machines. Typical applications for this capability are NVH (Noise, Vibration, Harshness) testing of vehicles and advanced vibration analysis of turbine machines. It accurately calculates the order spectrum, order traces, filtered or unfiltered orbits, gap reading and the centerline of a shaft during a start-up or coast-down process. The VP5 Vibration Data Collector’s order tracking algorithm performs digital re-sampling of the measured signal for ensure data accuracy. The order spectrum data can be displayed on a waterfall plot or intensity map. Cut a slice or a trace of data from the waterfall plot and then examine the individual traces. As shown in the figure below, the user can enter the geometric position(s) of the vibration sensor(s) to create a plot to display orbit and shaft centerline motion, which relates to the realistic behavior of a turbine machine.

Raw Data Recorder Module

The optional Raw Data Recorder Module directly records raw time data to the built-in compact flash card. For example, a 1 GB file will contain approximately three hours of continuous data with four channels recording at 2 kHz bandwidth. Benstone’s computer-based Novian Dynamic Signal Analyzer Software allows for playback and post-processing of raw data recorder files, such as FFT, order tracking or octave analysis.

Rotor Balancing module

The optional Rotor Balancing Module is a field balancing software package for rotating machines that utilizes industry-leading rotor balancing techniques: single-plane, dual-plane, overhung dual-plane, 3-plane, 4-plane, and 3-weights balancing. This advanced software simplifies field balancing of machines with a very high level of accuracy. Now with multiple-point balancing, vibration is minimized in BOTH horizontal and vertical directions at the same time. By enabling coast-down measurements for 1X vibration, the heavy spot is identified correctly with only one measurement, saving you time and money by eliminating the use of trial weights. It also eliminates safety concerns from placing the trial weights in the wrong location.

MP5 Handheld Vibration Data Collector

MP5 4-channel Handheld Vibration Analyzer

• Four channel portable vibration data collector and vibration analyzer

• High quality housing by dual injection molding process

• 5″ color touch screen

• Route based data aquisition

• Optional bump test module

• Optional ODS test module

• Optional balancing module

MP5 Handheld Vibration Analyzer

MP5 Handheld Vibration Analyzer is a compact portable 4 channel data collector that is designed for route-based data acquistion. With optional software modules, MP5 handheld vibration analyzer can conduct field balancing, ODS testing and Bump Testing as well. For measurements in harsh environments, MP5 is manufactured with a ruggedized housing by a dual injection molding process and protective sealing to provide an IP 65 rating. MP5 is equipped with a large 5-inch color (800 x 480 high resolution) touch screen. The combination of Microsoft’s powerful WinCE operating system and touch screen operation provides a user friendly and intuitive interface. MP5 acquires measurement signal with precision 24-bit sigma delta AD converters to provide a high dynamic range, up to 40 kHz maximum bandwidth.

Route Based Data Collector and Portable Vibration Analyzer

Combined with iSee, the powerful PC software built for machinery condition monitoring project, MP5 Handheld Vibration Analyzer is your best choice for route-based data acquisition. MP5 supports simultaneous tri-axial vibration measurement, saving many work hours in the field. MP5 measures bearing fault signal via true peak detection on a high-pass filtered time waveform. This field-proven portable vibration analyzer provides sensitive and accurate readings from the early stage of bearing damage, and you can track the damage development from the trending analysis feature of iSee PC software.

Envelope spectrum measurement is a standard vibration analysis feature for confirming bearing failure. Temperature and other process parameter measurements are also supported by this handheld vibration analyzer.

Bump Test Module

MP5 Handheld Vibration Analyzer’s powerful Bump Test module allows you to conduct bump test on a structure and measure its FRF, coherence, and cross power spectrum functions. This useful module helps you to investigate the resonance of a machine, conduct structural reinforcement and reduce the vibration level of a machine running at resonance zone. The test data can be imported to a 3rd party software, like ME’Scope, for further modal analysis to derive its modal shapes, natural frequencies and damping values.

ODS Test module

MP5 Handheld Vibration Analyzer’s ODS Test module allows you to conduct ODS test on a running machine and measure its FRF, coherence, and cross power spectrum functions. With the reference vibration sensor connected to channel 1, and a triaxial vibration sensor connected to channel 2, 3 and 4, MP5 saves your time for the measuring tasks in the field via real-time four channel measurements. By importing the test data to a 3rd party software, like ME’Scope, you may derive the Operational Deflection Shapes of your machines easily. The ODS test helps to find out how the structure deflects at certain running speed, provide useful information for structural reinforcement.

Field Rotor Balancing

The MP5 portable vibration analyzer with the (optional) balancing software package can balance your rotating machines in the field with industry leading balancing techniques like; single plane, dual plane, overhung dual plane, 3 plane, 4 plane and 3 weights balancing. This advanced balancing software makes it very simple to balance machines in the field with a very high level of accuracy. Now with multiple-point balancing, vibration in BOTH horizontal and vertical directions are minimized at the same time. By enabling coast-down measurements for 1X vibration, the heavy spot is identified correctly with only one measurement, saving you time, money and increasing safety. This technique prevents the user from danger by putting the trial weights in the wrong place and shortens the time required for rotor balancing. Other rotor balancing features / functions are:

● Multi-point balancing

● Component calculation

● Drill depth calculation

● Allowable residual unbalance calculated from the ISO 1940 standard

● Unequal radii calculation

● Decoupled balancing (couple + static)

● Review historical vibration data on a polar plot.

● Review historical balancing data on a polar plot

● Heavy spot estimation with one shot measurement.

● Redo a previous balancing job with saved balancing factors.

● Continue an unfinished balancing job from a saved file

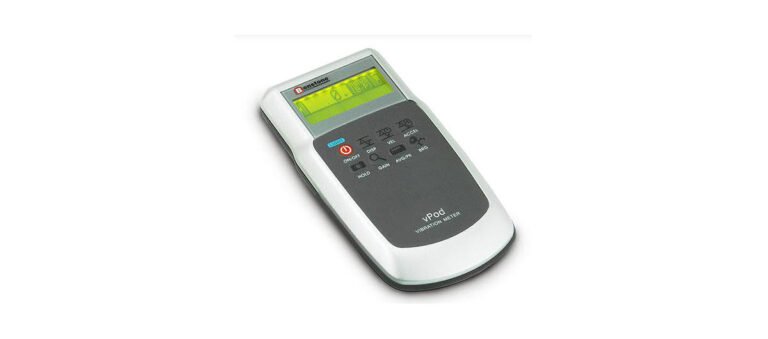

vPod Vibration Meter

vPod Lite is a microprocessor based smart vibration meter

• Measure vibration levels in acceleration, velocity, and displacement

• User-selectable vibration units and detection (rms, peak, peak-peak)

• Display vibration unit and detection on the LCD screen

• Automatically detect and display sensor and cable status with an icon

• Turn on screen back light in dark environment

• Display battery indicator on the screen

• Adjustable sensor sensitivity when the sensor is changed

vPod Smart Vibration Meter SeriesThe microprocessor-powered by vPod family of vibration meters can easily measure average, hold or peak hold vibration data, and display them with user-selectable unit/detection. The battery charge indicator and sensor bias indicator are also standard feature. For precision machines that have very low vibration levels, a precision reading is necessary. In addition to an extra quiet accelerometer – that is supplied as a standard accessory – a built-in gain circuit amplifies low-level vibration signals and show readings in precision mode when you turn the gain mode on. This one button gain function allows the user to increase precision by one decimal point. The vPod vibration meters can measure vibration levels in acceleration, velocity or displacement. The user-selected display presents the vibration data in their preferable units and detections. The vPod vibration meters come standard with a built-in 500 Hz high pass filter. This is significant because most roller element bearings’ parts are located between 500 Hz – 2 kHz. This high pass filter is a proven bearing tester method for early detection of bearing failure. |

SMD (surface mount) production ● Battery charge indicator |

Compared with vPod Lite, vPod vibration meter has additional features as follows:

• A high-pass filtered acceleration level bearing tester

• Precision mode for resolution of 0.1 micro-meter

• Measure averaged data, peak-hold data, or freeze the display

vPod II route-based vibration data collector

• Stores up to 1000 points of vibration data

• Vibration data can be transferred to a PC via the USB connection

A complete vPod vibration meter kit comes with

• A hard carrying case

• A high quality IEPE accelerometer

• A coiled cable

• A magnetic base

• A probe tip

• A soft carrying case

• An user manual

• PC software for data transfer and a USB cable (for vPod II)