Vinco Ball Valves

- Industrial Range

- Oil and Gas Range

- Cryogenic Range

- Sanitary Range

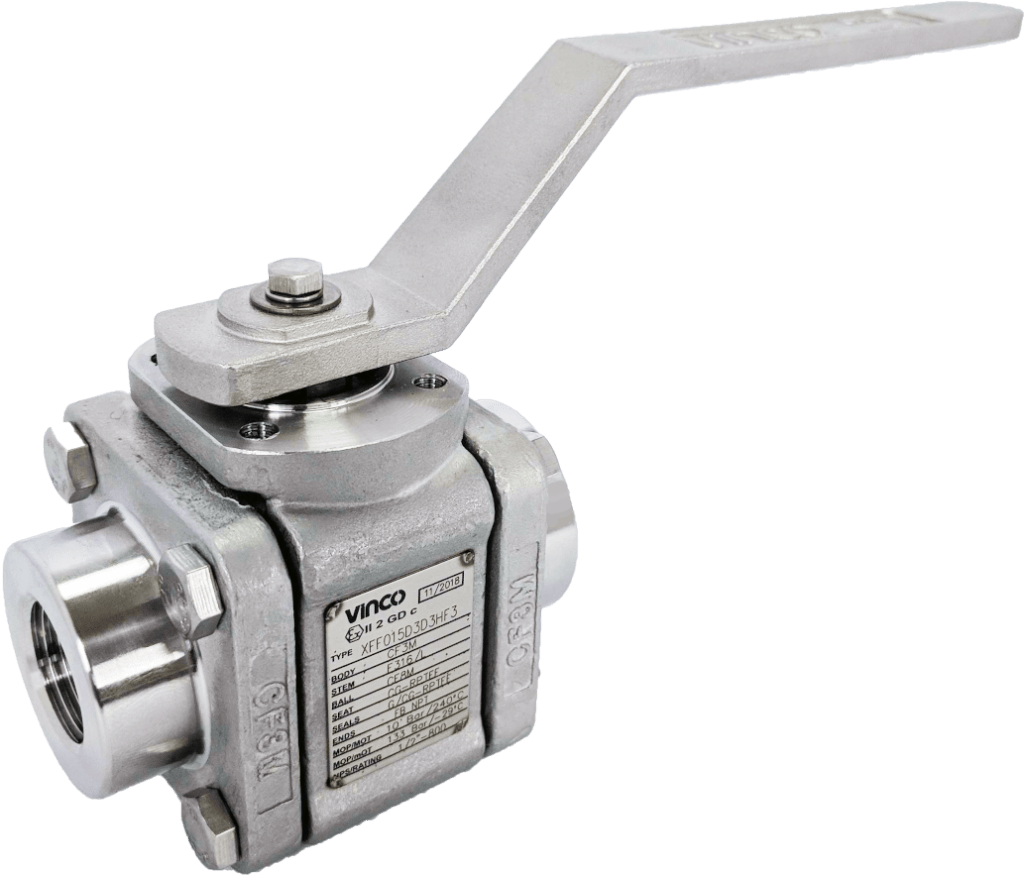

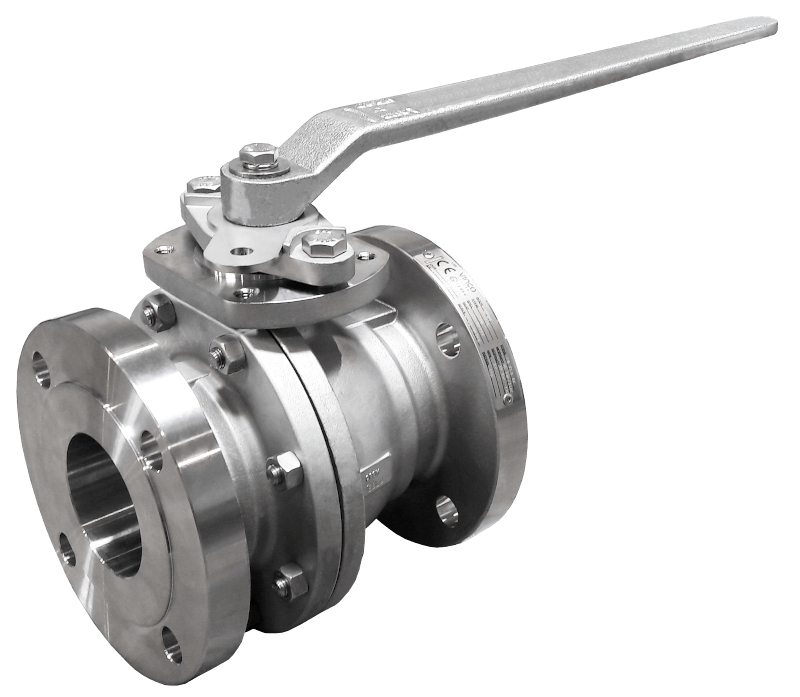

Industrial Range Ball Valves

Class:

600/300 ( 100/50 bar)

Reduce Bore:

DN15 (1/2″) to DN100 (4″)

Full Bore:

DN10 (3/8″) to DN100(4″)

Construction Standards:

ASME B16.34; ISO 17292; ISO 14313; MSS SP-25

Body/ End Connections:

WCB; CF3M; CF8

Seats/ seals:

C-RPTFE; TFM; PEEK; PEEK MOD; DEVLON; UHMWPE

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

Class:

800/600/300 ( 138/100/50 bar)

Reduce Bore:

DN15 (1/2″) to DN100 (4″)

Full Bore:

DN10 (3/8″) to DN100(4″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A105N-LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / TITANIUM B348 Gr.2 / OTHERS

Seats/ seals:

CG-RPTFE; GL-RPTFE; TFM; PEEK; PEEK MOD; PEEK DEVLON; UHMWPE

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

Class:

900/1500/2500 (150/248/414 bar)

Reduce Bore:

DN15 (1/2″) to DN100 (4″)

Full Bore:

DN10 (3/8″) to DN80(3″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / INCONEL 625 / OTHERS

Seats/ seals:

CG-RPTFE; GL-RPTFE; TFM; PEEK; PEEK MOD; PEEK DEVLON; UHMWPE

Packing:

Graphite + Peek

Bolting

A193 Gr.B7 / A320 Gr.L7 / A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according to ASME B16.10

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

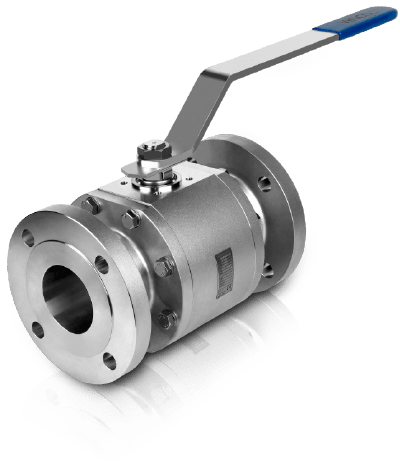

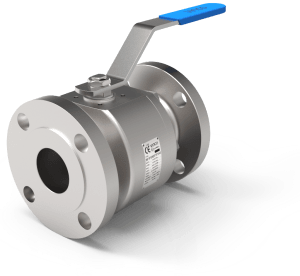

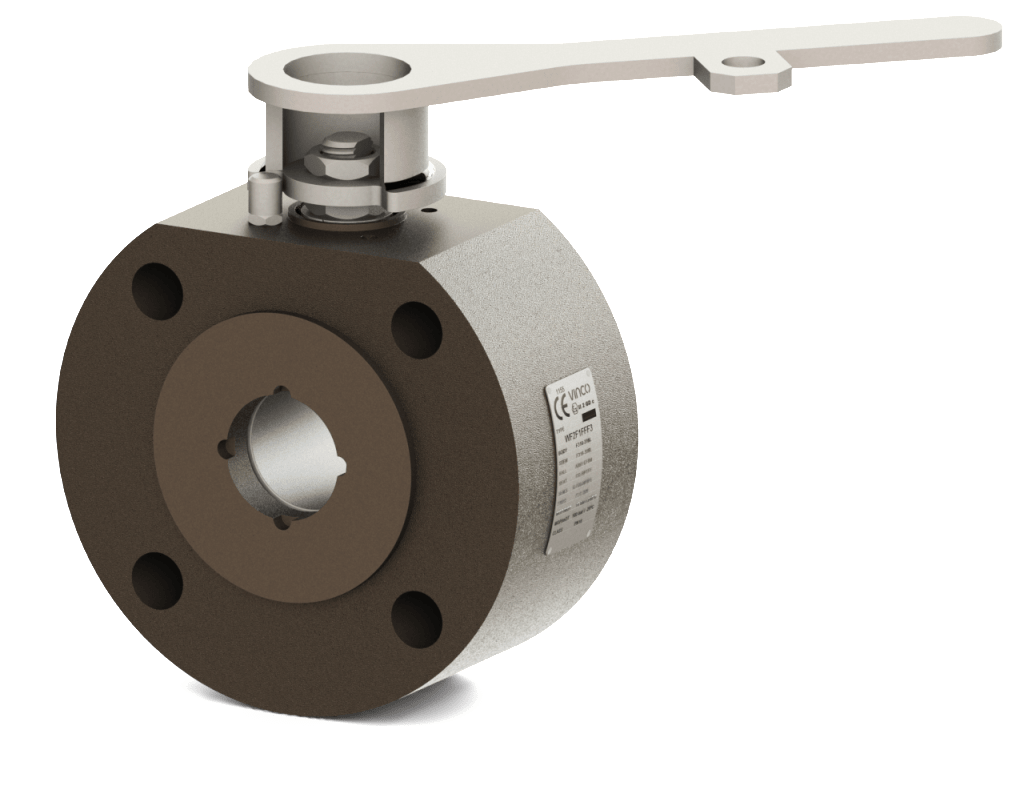

Class:

150/300 (20,7/51,7 bar)

Full Bore:

DN15 (1/2″) to DN150(6″)

Construction Standards:

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25

Body/ End Connections

WCB/ LCC/ CF8M

Seats/Seals

C-RPTFE / PEEK / PTFE / TFM 1600 / DEVLON / UHMWPE

Packing

Graphite + Peek

Bolting

A193 Gr.B7 / A320 Gr.L7 / A193 Gr.B8M

Flanged Ends

RF – ASME B16.5

Face to face according ASME B16.10

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

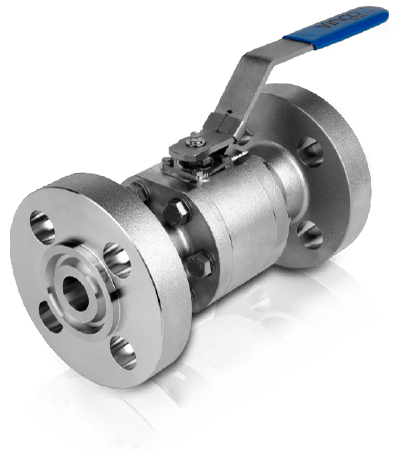

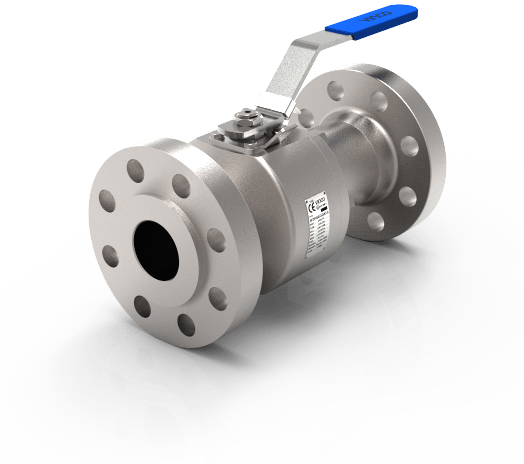

Class:

150/300/600 (20,7/51,7/103,5 bar)

Reduce Bore:

DN50 (2″) to DN150 (6″)

Full Bore:

DN15 (1/2″) to DN150(6″)

Construction Standards:

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25

Body/ End Connections

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / TITANIUM B348 Gr.2 / OTHERS

Seats/Seals

CG-RPTFE / PEEK / PTFE / TFM 1600 / DELRIN / DEVLON / UHMWPE

Packing

Graphite + Peek

Bolting

A193 Gr.B7 / A320 Gr.L7 / A193 Gr.B8M

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Flanged DIN PN16/40/63/100 – DIN EN 1092-1

Face to face according to DIN 3202-1

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

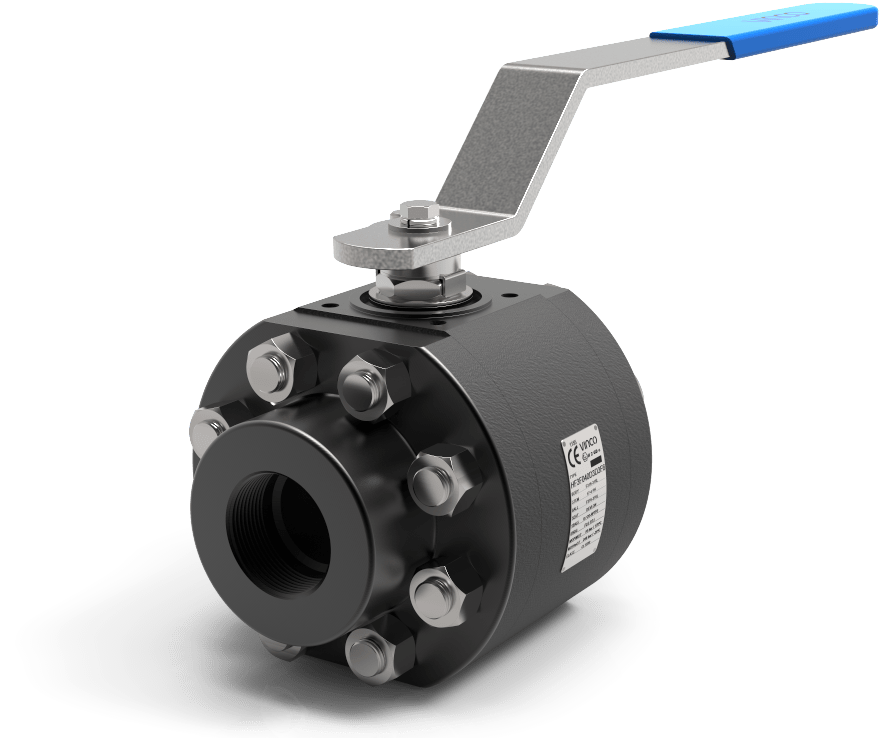

Class:

DIN PN100/ 160

Full Bore:

DN15 (½”) to DN150 (6”)

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25 / ISO 5211

Body/End Connections

A350 LF2 / OTHERS

Seat/ Seals

DELRIN / DEVLON

Packing

GRAPHITE + PEEK

Bolting

CARBON ST ZINC.

Flanged DIN

PN16/40/63/100 – DIN EN 10921

Flanged Ends

ASME B16.5

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

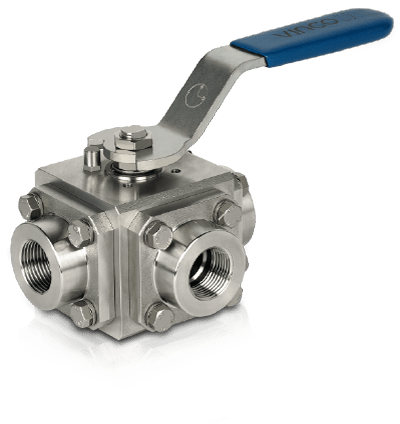

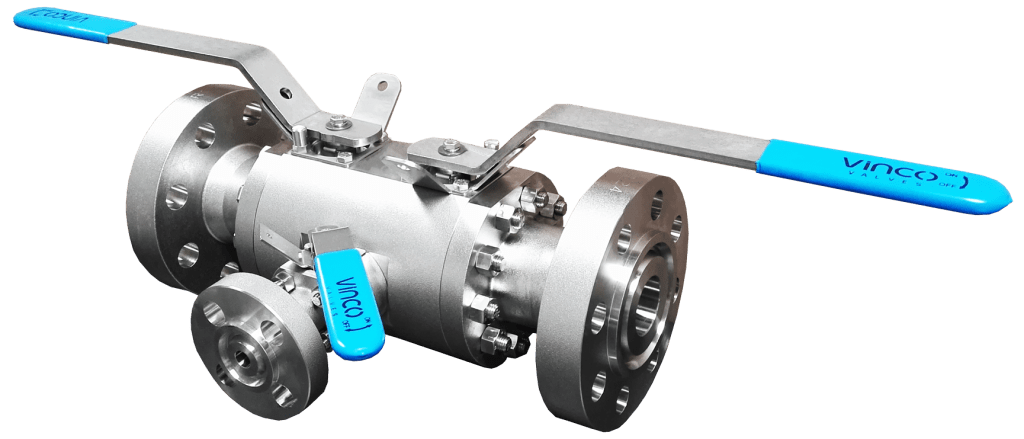

Class:

600/ 300/ 150

Full Bore:

DN10 (3/8 ”) to DN100(4 ”)

Reduce Bore:

DN15 (1/2”) to DN 150 (6”)

Ball Port:

L, T, X Transflow or Non-transflow

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25

Body/End Connections

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / TITANIUM B348 Gr.2 / OTHERS

Seat/ Seals

CG-RPTFE / PEEK / PTFE / TFM 1600 / DELRIN / DEVLON / UHMWPE

Packing

Graphite + Peek

Bolting

A193 Gr.B8 /A193 Gr.B8M /A193 Gr.B7 /A320 Gr.L7 /A194 Gr.8 /A194 Gr.8M /A194 Gr.7LM

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Flanged DIN

PN16/40/63/100 – DIN EN 1092-1

Face to face according to DIN 3202-1

Buttweld Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according to ASME B16.10

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

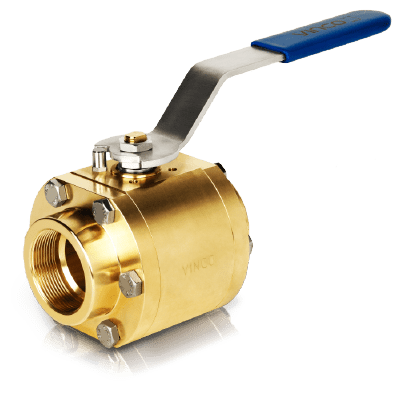

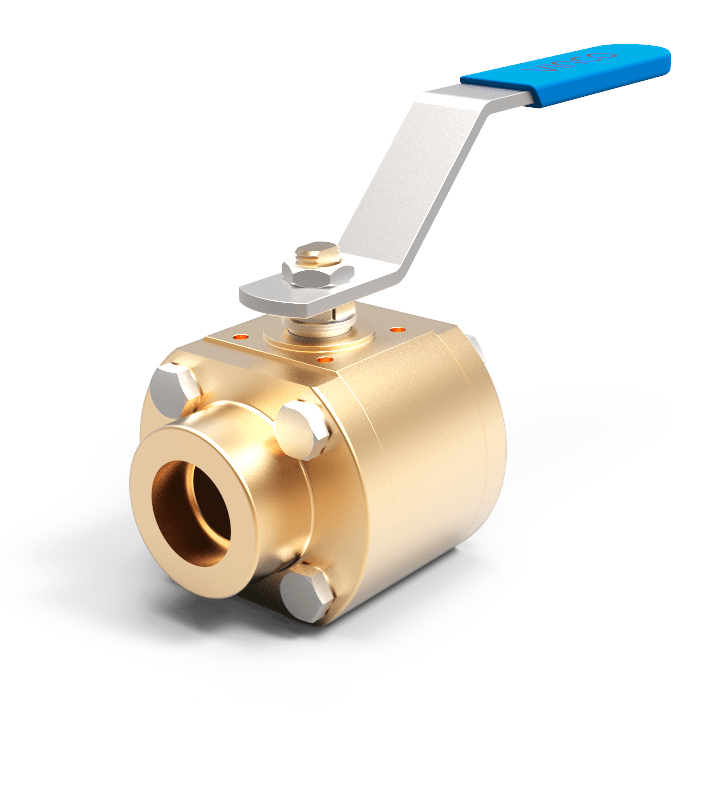

Class:

Cl300

Full Port:

DN 10 (3/8’’) to DN 50 (2’’)

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP25

Body/End Connections

BS1400 LG4/ BS1400 AB2/ OTHERS

Seat/ Seals

PTFE / TFM 1600

Packing

PTFE

Bolting

SS. 304

Threaded Ends

BSP/BSPP – ISO 2281

BSPT – ISO 71 / EN 102261/2

NPT – ASME B1.20.1

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

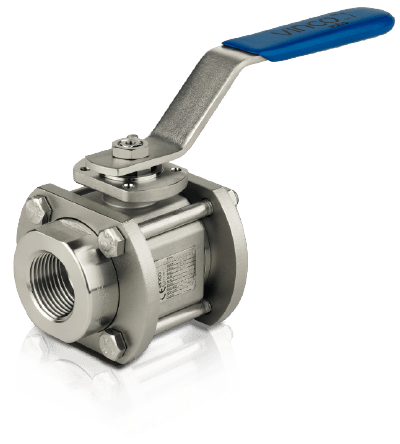

Class:

600/400 (100/64 bar)

Full Bore:

DN10 (3/8”) to DN50 (2’’)

Reduce Bore:

DN15 (1/2”) to DN65 (2 ½”)

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP25/ ISO 5211

Body/End Connections

A351 CF3M / OTHERS

Seat/ Seals

PTFE / TFM 1600

Packing

PTFE

Bolting

SS. 304

Threaded Ends

BSP/BSPP – ISO 2281

BSPT – ISO 7-1 / EN 102261/2

NPT – ASME B1.20.1

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

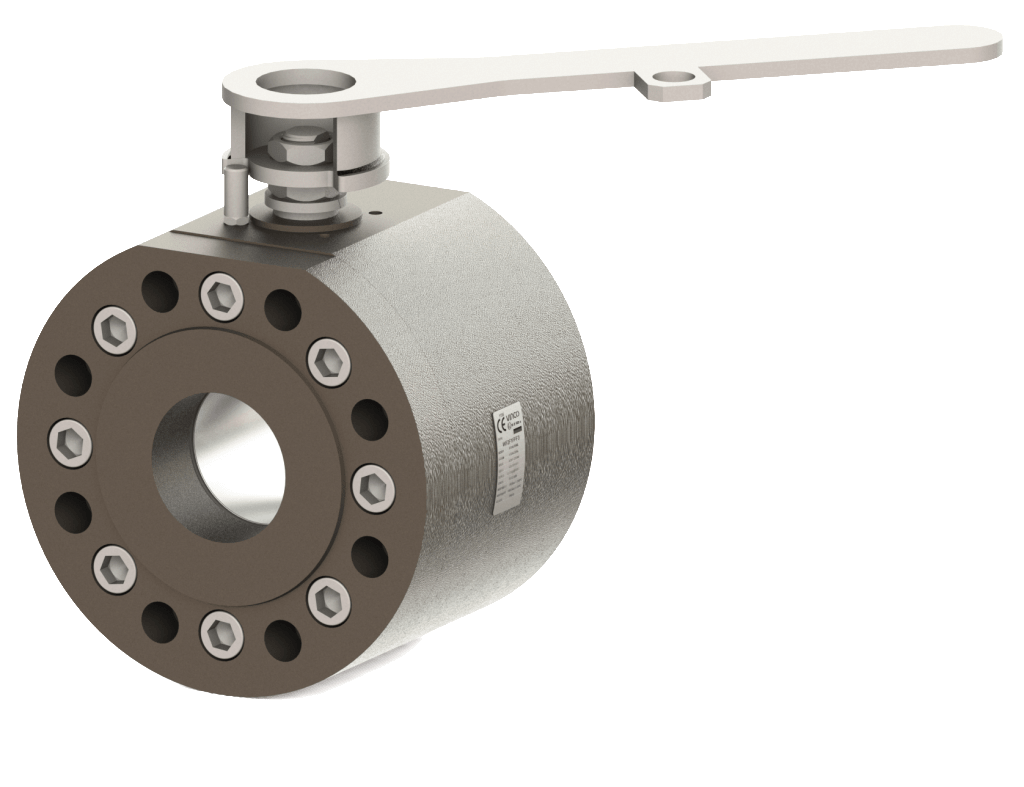

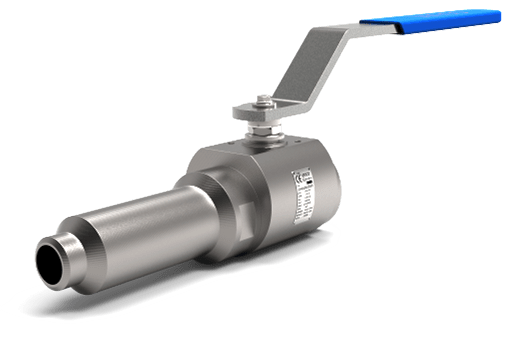

Class:

2500

Full Bore:

DN10 (3/8 ”) to DN50 (2”)

Reduce Bore:

DN15 (1/2”) to DN65 (2 ½”)

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25 / ISO 5211

Body / End Connections

A350 LF2 /A182 F316-316L /A182 F304-304L /A182 F51 /A182 F55 /A182 F44 /A182 F321 /OTHERS

Seats/ Seals

DEVLON / PEEK

Packing

Graphite + Peek

Threated Ends

BSP/BSPP – ISO 228-1 <br< bspt=”” –=”” iso=”” 7-1=”” en=”” 10226-½<br=””>NPT – ASME B1.20.1

Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25</br<>

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

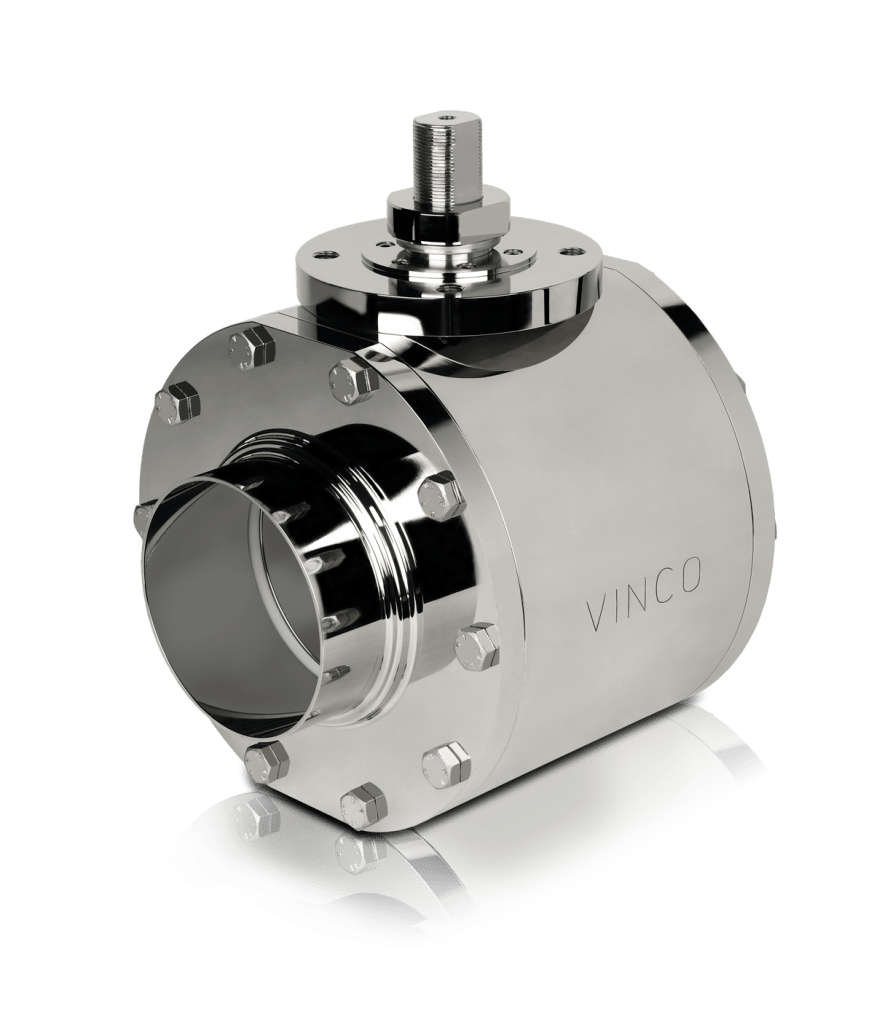

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN300 (12″)

Full Bore:

DN15 (1/5″) to DN300(12″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

CG-RPTFE; PEEK; DEVLON; OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Lockable Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Gear Box

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

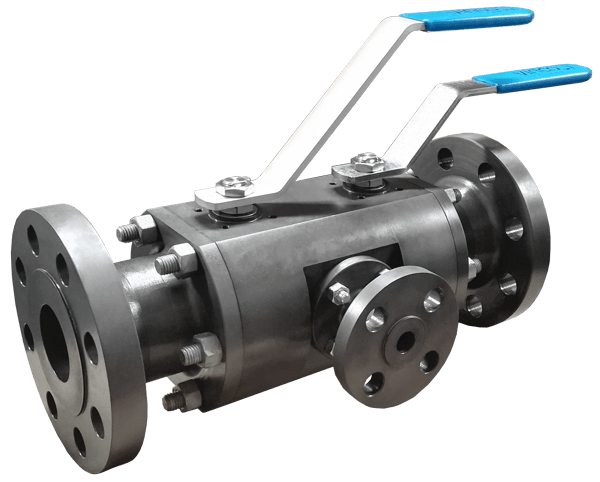

DF/DFM SERIES

Double Block and Bleed (Twin Ball) – Floating Ball – Soft / Metal Seated – Fire Safe – Atex

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN50 (2″)

Full Bore:

DN15 (1/5″) to DN50 (2″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

CG-RPTFE; PEEK; DEVLON; A182 F316-316L + TCC OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Bleed Valve:

Needle or Floating

Lockable Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Gear Box

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

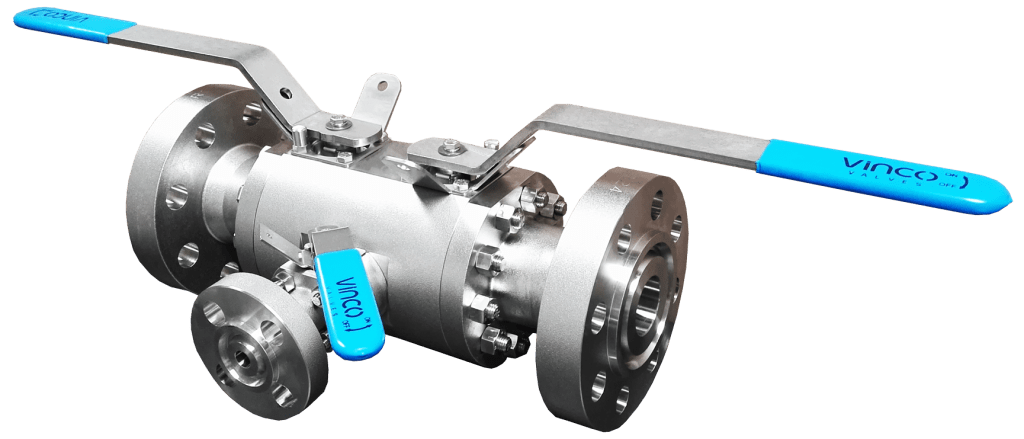

DTR/DTM SERIES

Double Block and Bleed (Twin Ball) – Truunion Ball – Soft / Metal Seated – Fire Safe – Atex

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN50 (2″)

Full Bore:

DN15 (1/5″) to DN50 (2″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

CG-RPTFE; PEEK; DEVLON; A182 F316-316L + TCC OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Bleed Valve:

Needle or Floating

Lockable Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Gear Box

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

METAL SEATS

3 Pieces Bolted or Split Body – Floating or Trunnion Ball – Fire Safe – Atex

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN300 (12″)

Full Bore:

DN15 (1/5″) to DN300(12″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

A182 F316-316L + TCC (Tungsten Carbide Coating); Graphite; OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Lockable Handle

Extended Stem

Bracket for Automation

Actuator

Gear Box

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

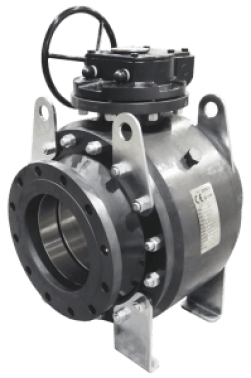

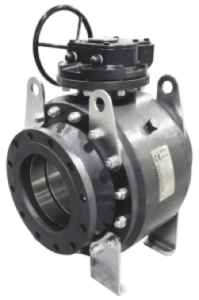

Oil and Gas Range

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN300 (12″)

Full Bore:

DN15 (1/5″) to DN300(12″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

CG-RPTFE; PEEK; DEVLON; OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Lockable Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Gear Box

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

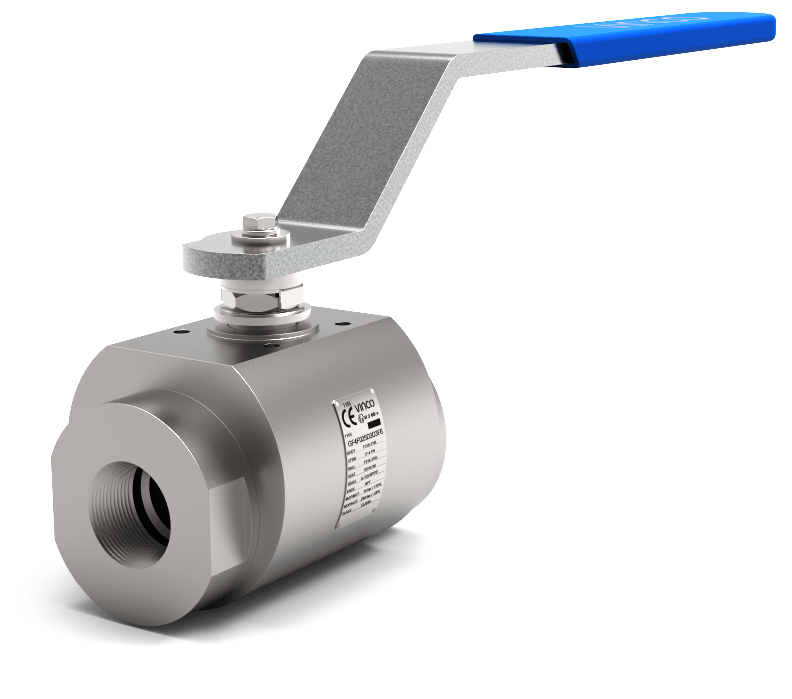

Class:

800/600/300 ( 138/100/50 bar)

Reduce Bore:

DN15 (1/2″) to DN100 (4″)

Full Bore:

DN10 (3/8″) to DN100(4″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A105N-LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / TITANIUM B348 Gr.2 / OTHERS

Seats/ seals:

CG-RPTFE; GL-RPTFE; TFM; PEEK; PEEK MOD; PEEK DEVLON; UHMWPE

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

Class:

900/1500/2500 (150/248/414 bar)

Reduce Bore:

DN15 (1/2″) to DN100 (4″)

Full Bore:

DN10 (3/8″) to DN80(3″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / INCONEL 625 / OTHERS

Seats/ seals:

CG-RPTFE; GL-RPTFE; TFM; PEEK; PEEK MOD; PEEK DEVLON; UHMWPE

Packing:

Graphite + Peek

Bolting

A193 Gr.B7 / A320 Gr.L7 / A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according to ASME B16.10

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

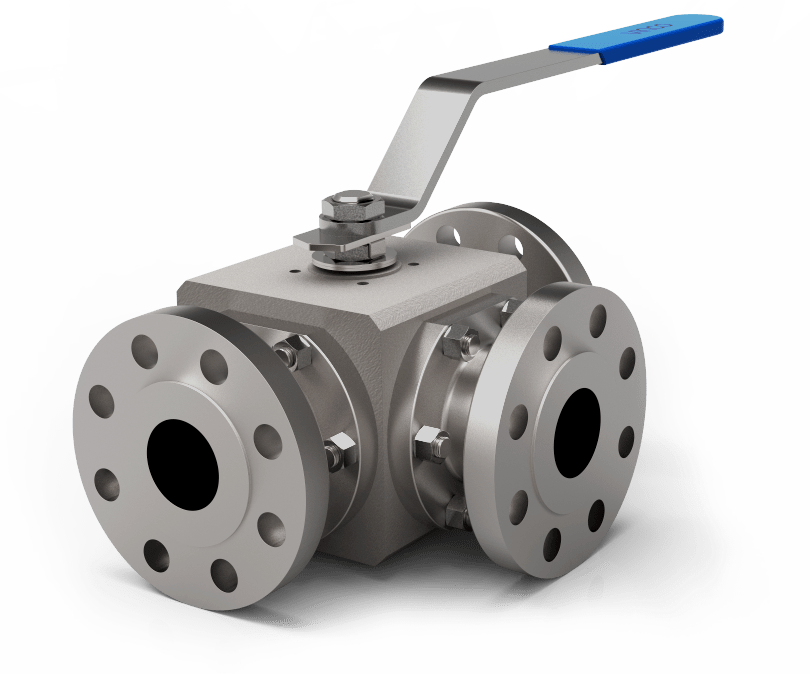

Class:

150/300/600 (20,7/51,7/103,5 bar)

Reduce Bore:

DN50 (2″) to DN150 (6″)

Full Bore:

DN15 (1/2″) to DN150(6″)

Construction Standards:

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25

Body/ End Connections

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / TITANIUM B348 Gr.2 / OTHERS

Seats/Seals

CG-RPTFE / PEEK / PTFE / TFM 1600 / DELRIN / DEVLON / UHMWPE

Packing

Graphite + Peek

Bolting

A193 Gr.B7 / A320 Gr.L7 / A193 Gr.B8M

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Flanged DIN PN16/40/63/100 – DIN EN 1092-1

Face to face according to DIN 3202-1

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

Class:

600/ 300/ 150

Full Bore:

DN10 (3/8 ”) to DN100(4 ”)

Reduce Bore:

DN15 (1/2”) to DN 150 (6”)

Ball Port:

L, T, X Transflow or Non-transflow

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25

Body/End Connections

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / A182 F321 / TITANIUM B348 Gr.2 / OTHERS

Seat/ Seals

CG-RPTFE / PEEK / PTFE / TFM 1600 / DELRIN / DEVLON / UHMWPE

Packing

Graphite + Peek

Bolting

A193 Gr.B8 /A193 Gr.B8M /A193 Gr.B7 /A320 Gr.L7 /A194 Gr.8 /A194 Gr.8M /A194 Gr.7LM

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Flanged DIN

PN16/40/63/100 – DIN EN 1092-1

Face to face according to DIN 3202-1

Buttweld Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according to ASME B16.10

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

Class:

2500

Full Bore:

DN10 (3/8 ”) to DN50 (2”)

Reduce Bore:

DN15 (1/2”) to DN65 (2 ½”)

Construction Standard

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25 / ISO 5211

Body / End Connections

A350 LF2 /A182 F316-316L /A182 F304-304L /A182 F51 /A182 F55 /A182 F44 /A182 F321 /OTHERS

Seats/ Seals

DEVLON / PEEK

Packing

Graphite + Peek

Threated Ends

BSP/BSPP – ISO 228-1 <br< bspt=”” –=”” iso=”” 7-1=”” en=”” 10226-½<br=””>NPT – ASME B1.20.1

Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25</br<>

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

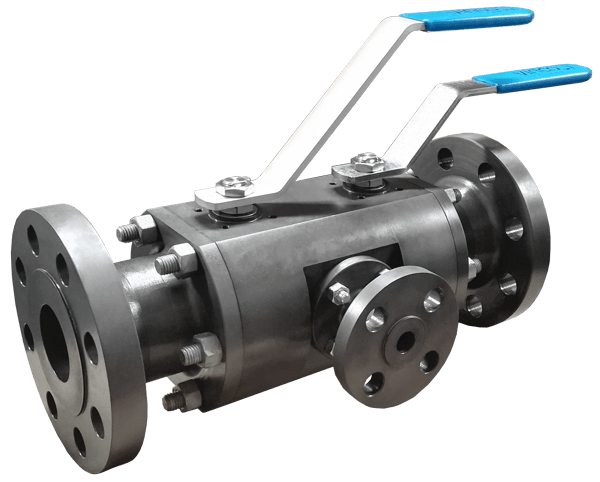

DF/DFM SERIES

Double Block and Bleed (Twin Ball) – Floating Ball – Soft / Metal Seated – Fire Safe – Atex

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN50 (2″)

Full Bore:

DN15 (1/5″) to DN50 (2″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

CG-RPTFE; PEEK; DEVLON; A182 F316-316L + TCC OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Bleed Valve:

Needle or Floating

Lockable Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Gear Box

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

DTR/DTM SERIES

Double Block and Bleed (Twin Ball) – Truunion Ball – Soft / Metal Seated – Fire Safe – Atex

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN50 (2″)

Full Bore:

DN15 (1/5″) to DN50 (2″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

CG-RPTFE; PEEK; DEVLON; A182 F316-316L + TCC OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Bleed Valve:

Needle or Floating

Lockable Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Gear Box

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

METAL SEATS

3 Pieces Bolted or Split Body – Floating or Trunnion Ball – Fire Safe – Atex

Class:

150 to 2500 ( 20,7 to 414 bar)

Reduce Bore:

DN20 (3/4″) to DN300 (12″)

Full Bore:

DN15 (1/5″) to DN300(12″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A350 LF2 / A182 F316-316L / A182 F304-304L / A182 F51 / A182 F55 / A182 F44 / OTHERS

Seats/ seals:

A182 F316-316L + TCC (Tungsten Carbide Coating); Graphite; OTHERS

Packing:

Graphite + Peek

Bolting

A193 Gr.B7/ A320 Gr.L7/ A193 Gr.B8M

Threaded Ends

BSP/BSPP – ISO 228-1

BSPT – ISO 7-1 / EN 10226-½

NPT – ASME B1.20.1

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Lockable Handle

Extended Stem

Bracket for Automation

Actuator

Gear Box

Fire Safe Design according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

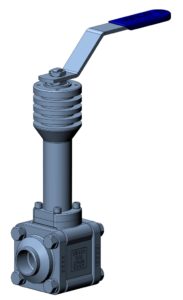

Cryogenic Range

Class:

600/300 ( 138/100/50 bar)

Reduce Bore:

DN15 (1/2″) to DN50 (2″)

Full Bore:

DN10 (3/8″) to DN100(4″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A351 CF3M / OTHERS

Seats/ seals:

CG-RPTFE; GL-RPTFE; TFM; PEEK; PCTFE

Packing:

Graphite + Peek

Bolting

A193 Gr.B8M

Buttweld and Buttweld Nipple Ends

BW (Sch.10 to XXS) – ASME B36.10M and B16.25

Socketweld and Socketweld Nipple Ends

SW – ASME B16.11

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

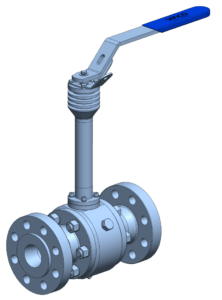

Class:

150/300 (20/50 bar)

PN16/40

Full Bore:

DN15 (1/2″) to DN200(8″)

Construction Standards:

ASME B16.34; ISO 17292; API 6D; ISO 14313; MSS SP-25

Body/ End Connections:

A351 CF8M / OTHERS

Seats/ seals:

CG-RPTFE; GL-RPTFE; TFM; PEEK;PCTFE

Packing:

Graphite + Peek

Bolting

A193 Gr.B8M

Flanged Ends ASME

RF and RTJ – ASME B16.5

Face to face according to ASME B16.10

Flanged Ends DIN PN16/40 – DIN EN 1092-1

Face to face according to DIN 3202-1

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

Class:

150 up to 1500

Reduce Bore:

DN50 (2″) to DN150 (6″)

Full Bore:

DN15 (1/2″) to DN150(6″)

Construction Standards:

ASME B16.34 / ISO 17292 / API 6D / ISO 14313 / MSS SP-25

Body/ End Connections

A182 F316-316L / A182 F304-304L / OTHERS

Seats/Seals

CG-RPTFE / PEEK / PTFE / TFM 1600 / PCTFE

Packing

Graphite + Peek

Bolting

A193 Gr.B8M

Flanged Ends

RF and RTJ – ASME B16.5

Face to face according ASME B16.10

Flanged DIN PN16/40/63/100 – DIN EN 1092-1

Face to face according to DIN 3202-1

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

Fire Safe Certification according to ISO 10497 and API 607 Ed.6

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to EN 12266-1 Rate A and API 598 / ISO 5208

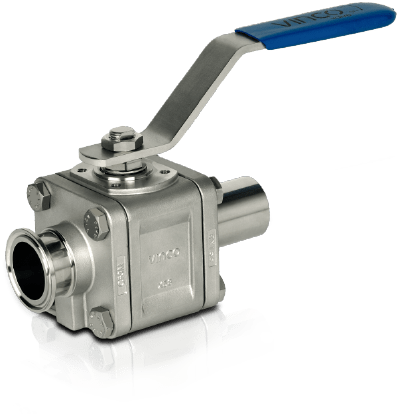

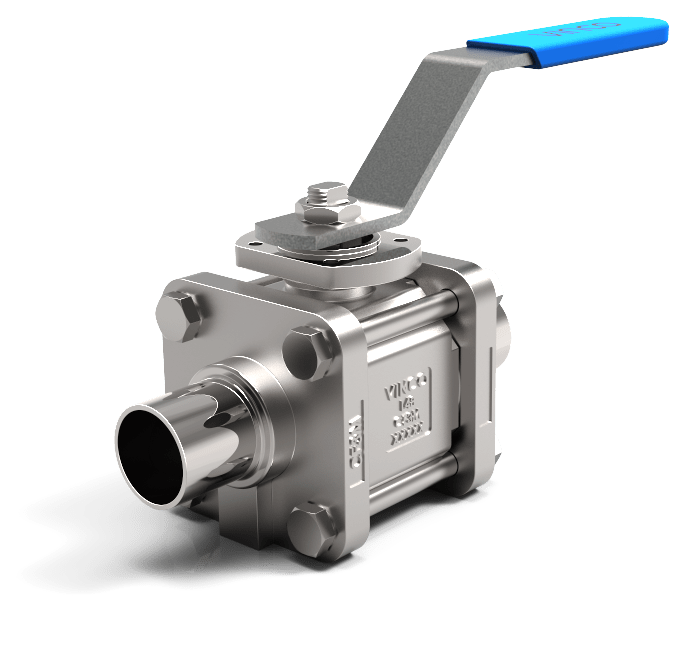

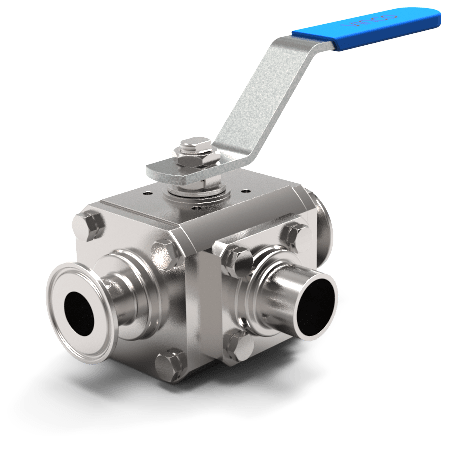

Sanitary Range

Class:

ASME BPE/ DIN 11850/ ISO 1127/ SMS 3008

True Bore:

DN8 (¼”) to DN150 (6”)

Construction Standard

ASME BPE / ASME B16.34 / ISO 17292 / ISO 5211

Body/ End Connections

A351 CF3M

Sulphur: 0,005 to 0,017% to integrity of orbital welding

Ferrite: less than 2% to prevent corrosion

Seats/Cavity Fillers/Seals:

TFM 1600 / PTFE

Packing

TFM 1600 / PTFE

Bolting

SS. 304

Extended Buttweld Ends

ASME BPE TUBE / DIN 11850 TUBE / ISO 1127 TUBE / SMS 3008 TUBE

Hygienic Clamp Ends

ASME BPE TUBE / DIN 11850 TUBE

Interior Mechanical Polishing

Ra of less than 0,50 μm

Option

Ra 0, 25 micrometer (10μ in) and electro-polishing

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to ASME BPE

FDA & UPS Class VI certificate of compliance for nonmetallic parts

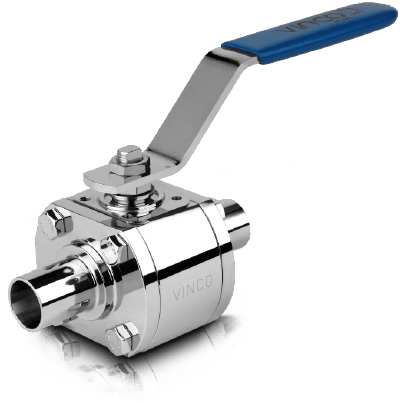

Class:

ASME BPE/ DIN 11850/ ISO 1127/ SMS 3008

True Bore:

DN8 (¼”) to DN150 (6”)

Construction Standard

ASME BPE 2012 / ASME B16.34 / ISO 17292 / ISO 5211

Body/End Connections

A182 F316-316L/ 1.4435 BN2/ HASTELLOY C22/ C276/ TITANIUM B348 Gr.2/ AL6XN (UNS N08367)/ OTHERS

Seats/Cavity Fillers/Seals

TFM 1600/ PEEK/ PTFE

Packing

TFM 1600/ PTFE

Bolting

SS. 304

Extended Buttweld Ends

ASME BPE TUBE / DIN 11850 TUBE / ISO 1127 TUBE / SMS 3008 TUBE

Hygienic Clamp Ends

ASME BPE TUBE / DIN 11850 TUBE

Interior Mechanical Polishing

Ra of less than 0,50 μm

Exterior Mechanical Polishing

Ra 0,75 micro polished

Option

Ra 0, 25 micrometer (10μin) and electropolishing

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to ASME BPE

FDA & UPS Class VI certificate of compliance for nonmetallic parts

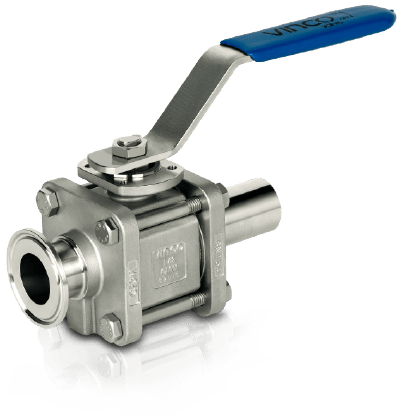

Class:

ASME BPE/ DIN 11850/ ISO 1127/ SMS 3008

True Bore:

DN8 (¼”) to DN50 (2”)

Construction Standard

ASME BPE 2012 / ASME B16.34 / ISO 17292 / ISO 5211

Body/ End Connections

A351 CF3M/ A351 CF3

Sulphur: 0,005 to 0,017% to integrity of orbital welding

Ferrite: less than 2% to prevent corrosion

Seats/Cavity Fillers/Seals:

TFM 1600 / PTFE

Packing

TFM 1600 / PTFE

Bolting

SS. 304

Extended Buttweld Ends

ASME BPE TUBE / DIN 11850 TUBE / ISO 1127 TUBE / SMS 3008 TUBE

Hygienic Clamp Ends

ASME BPE TUBE / DIN 11850 TUBE

Interior Mechanical Polishing

Ra of less than 0,50 μm

Exterior Mechanical Polishing

Ra 0,75 micro polished

Option

Ra 0, 25 micrometer (10μin) and electropolishing

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

ATEX II 2 GD Certification according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to ASME BPE

FDA & UPS Class VI certificate of compliance for nonmetallic parts

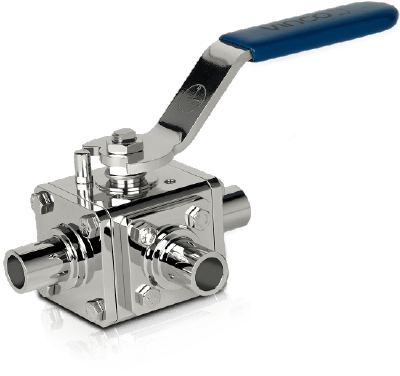

Class:

ASME BPE/ DIN 11850/ ISO 1127/ SMS 3008

True Bore:

DN8 (¼”) to DN100 (4”)

Construction Standard

ASME BPE 2012 / ASME B16.34 / ISO 17292 / ISO 5211

Body/ End Connections

A182 F316316L / 1.4435 BN2 / HASTELLOY C22/C276 / TITANIUM B348 Gr.2 / OTHERS

Seats/Cavity Fillers/Seals:

TFM 1600 / PTFE

Packing

TFM 1600 / PTFE

Bolting

SS. 304

Extended Buttweld Ends

ASME BPE TUBE / DIN 11850 TUBE / ISO 1127 TUBE / SMS 3008 TUBE

Hygienic Clamp Ends

ASME BPE TUBE / DIN 11850 TUBE

Interior Mechanical Polishing

Ra of less than 0,50 μm

Exterior Mechanical Polishing

Ra 0,75 micro polished

Option

Ra 0, 25 micrometer (10μin) and electropolishing

Lockable Handle

Spring Return Handle

Extended Stem

Limite Switches

Bracket for Automation

Actuator

ATEX II 2 GD Design according to 2014/34/EU

PED Certification according to 2014/68/EU

Ball valves are tested according to ASME BPE

FDA & UPS Class VI certificate of compliance for nonmetallic parts