Ultrasound Detection and Inspection Instruments

Assetmatrix Energy is proud to represent UE Systems line of Ultrasonic Inspection Instruments. UE Systems is the world leader in providing ultrasound instruments & training solutions for predictive maintenance, reliability, condition monitoring and energy saving programs. We assist companies worldwide implementing ultrasound technology in their maintenance & reliability best practices, by providing the right inspection instruments, the right training, license-free software and continuous support. By guiding companies in establishing and maturing an ultrasound inspection program, we assist them in achieving:

- Significant energy savings by finding compressed air leaks and faulty stream traps & reporting the savings opportunity

- Downtime reduction by monitoring the condition of bearings, preventing lubrication issues & identifying bearing failures at a very early stage

- Improvements in safety procedures by using ultrasound for discharge detection during electrical inspections, at a safe distance

ONTRAK

-Online Monitoring Systems -Avoid Unplanned Downtime

4SITE

-Continuous Monitoring -For Electrical Assets

RAS – REMOTE ACCESS SENSORS

-Inspect bearings remotely

4CAST

ULTRA-TRAK 750 – BEARING CONDITION & LUBRICATION MONITORING TRANSMITTER

-Continuous monitoring -Multiple applications

ECM-586

-Continuously monitoring -Detects arcing, tracking & corona

UCA-586

-Continuously monitoring -For contact applications

OnTrak

Remote IIoT Bearing Monitoring System

- Monitor bearings 24/7

- Always connected

- Early warning of bearing failure

- Avoid lubrication issues

- Easy to Install

- Scalable

The OnTrak is a 16 channel IIoT edge analytic device designed to deliver the earliest warning of bearing failure and lubrication issues, remotely.

Put an end to analyzing healthy bearings

On average, 80-90% of machines run without any impending issue. In fact, the condition measurements do not provide any indication of an upcoming mechanical problem; they just confirm that the machine condition is fine.

The OnTrak real-time bearing and lubrication monitoring system utilizing the Ultra-Trak 750 sensor is designed to provide the earliest warning sign of bearing failure and prevent lubrication issues with simplicity and scale in mind.

The OnTrak solution is ready to guard against unplanned downtime and product loss the minute it is installed. Get real-time prescriptive alerts notifying you of when a bearing requires lubrication, starting to degrade or entering into catastrophic failure with simple, easy to understand visualizations and alert messaging.

The OnTrak is designed for:

- Bearing condition monitoring

- Identifying low speed rotating machine defects

- Prevent Lubrication issues

- Identify pump cavitation

Ease of Installation

Designed to mount near the assets being monitored, the OnTrak requires fewer cables and installation time than traditional condition monitoring systems. The system is designed to make installation and commissioning as easy as possible – most systems can be up in running in 30 minutes or less!

- Each OnTrak has a unique ID, simply plug in and connect to internet and data will be streaming in only a few minutes.

- Add additional OnTrak systems with ease. Simply connect it to power and internet and it is immediately recognized and assigned to your system.

- Preconfigured with your unique tag ID’s and locations.

- Prebuilt dashboards and the ability for you to customize as much as you want, receive immediate insights from the moment it is turned on.

“IT” Friendly Communication Options

With three options to connect the OnTrak system, Ethernet, wi-fi, or cellular, gives you options on how to best integrate this system with your existing automation and IT infrastructure.

Built for IIoT

Designed to give you flexibility into how you store and visualize your data. With built-in functionality supporting REST API calls over an HTTP (or HTTPS), it makes moving data into IBM Watson, Microsoft Azure, AWS, PTC Thingworxs, and other platforms a breeze.

Condition Monitoring in Minutes

It accommodates up to 16 channels and built to scale from one system to hundreds, utilizing unique IDs and factory configuration, simply plug in, connect and data will be streaming in minutes.

OnTrak Cloud™

The optional preconfigured and fully customizable dashboards from the OnTrak Cloud lets you view machine and sensor data on the customizable visualization dashboard via any web browser on any device – phone, tablet, or laptop. Get alerts via email and text messages based on the criteria you select.

- Use OnTrak cloud device management to see the status of all your connected systems and remotely deploy changes.

- All data sent to the OnTrak cloud dashboard is timestamped and saved in a database for viewing

immediately, generating reports, and exporting to CSV files for importing to spreadsheets. - Select from a menu of visualization widgets (for example, single value, line charts, tables).

Actionable insights out of the box

The OnTrak provides prescriptive lubrication and health insights:

- Healthy Bearing – Do Nothing!

- Lubrication Required – 8dB above baseline indicates a lack of lubrication.

- Beginning of Failure – 16dB above baseline indicates damage to the bearing – a failure mode beyond lubrication alone.

- Close to Failure – 35dB above baseline indicates damage to the bearing a failure mode beyond lubrication alone.

Text and email alerts can be sent based on criteria you select. Pre-built alerts for lubrication, early onset of failure and critical failure come standard.

With this IIoT Bearing Condition Monitoring System, unplanned downtime and lubrication issues will be a thing of the past.

Starter Kit:

- OnTrak system (available with cell, wi-fi or ethernet connection.

- Up to 16 x Ultra-Trak 750 sensors

- Pre-configured from factory with your specifications.

- Pre-built dashboards and alert categories

- 1 year of OnTrak cloud

- Technical support & remote expert diagnostics

4Site

Online Monitoring Solutions for Critical Electric Transmission and Distribution Equipment

- Always Listening

- Non-Invasive

- Optimized Data

- Scalability

Online Monitoring Solutions for Critical Electric Transmission and Distribution Equipment

Always Listening

The 4Site is listening in real-time for the first sign of high frequency sounds produced by arcing, tracking & corona.

Non-Invasive

Utilizing the power of airborne ultrasound, there is no contact with the electrical components of the equipment being monitored, making installation safer and easier.

Optimized Data

The 4Site is designed to reduce data overload and alert by exception. While the 4Site is always listening, it will only transmit informative data if a threshold is crossed and eliminating the need to transmit healthy data.

Scalability

Each 4Site is designed to monitor up to 4 cabinets simultaneously in one unit.

Continuous Monitoring of Electrical Assets

When electrical systems such as switch gear, transformers, insulators or disconnects and splices fail, the results can be catastrophic. The average cost of a critical electrical asset failure is greater than $500K per event and with the aging equipment and less than 5% of critical electrical assets have continuous monitoring integrated, the time is now to efficiently monitor your critical electrical assets for the three common failure modes, arcing, tracking & corona.

Online continuous ultrasound inspection can be performed at all voltage levels (low, medium and high) and is used to detect:

- Corona

- Partial discharge or tracking

- Arcing

- Mechanical vibrations (transformers)

How Ultrasonic Electrical Inspection Works

Partial discharge/tracking, arcing and corona all produce ionization which disturbs the surrounding air molecules.

The 4Site detects high frequency sounds produced by these emissions. The specific sound quality of each type of emission and the intensity of the signal is recorded. These sounds are analyzed through ultrasound spectrum analysis software for diagnosis & reporting.

Normally, electrical equipment should be silent, although some equipment such as transformers may produce a constant 50 cycle hum, or some steady mechanical noises.

These should not be confused with the erratic, sizzling frying, uneven and popping sound of an electrical discharge.

Weight: 4.7 lbs. (2.1 kg)

RAS – Remote Access Sensors

Quickly and easily inspect enclosed or hard-to-reach bearings with UE Systems’ permanent mounted Remote Access Sensors.

- Easy installation

- Connects to Switch Box

- Quickly inspect up to 8 bearings

- Perfect for hard-to-reach bearings

- Inspect remotely and safely

- Can be connected to the 4Cast system

When accessibility is an issue, the Remote Access Sensor is the answer.

When accessibility is an issue, such as when a motor is contained within a closed cabinet, or a test point is in a hard-to-reach area, the Remote Access Sensor (RAS) is the answer.

Mount the RAS on the test point and run a cable to an access area where a RAM (Remote Access Module) can be connected. When the point is to be tested, plug the RAM into your Ultraprobe and take your reading. Installation is very simple and testing is really easy.

Just mount the RAS transducer on your test subject, attach a BNC cable, run the cable through an access hole. Now, every time you come by, just plug it into your Ultraprobe 9000, 10,000, 15,000 or 401, record your data and move on.

If you have multiple bearings on hard-to-reach areas, you can even make use of UE Systems’ Switch Boxes which will allow to test up to 8 bearings at once!

UE Systems Switch Box

When access or safety make it challenging to inspect a test point, the RAS Switchbox is your answer, making remote sensing quick, easy and safe.

Connect and test single or multiple points remotely. Permanently mount a RAS to a test point and run a coax cable to the Switch Box. Once connected, you may test up to 8 test points at a time. To test, attach a RAM (Remote Access Module) to the Switchbox, select a test point indicator and collect your data. It’s that easy!

The UE Switchbox can be used with the Ultraprobe 9000, 10,000, 15,000 and 401.

High-Temperature Applications

When the test object operates under high temperatures, we have a special Remote Access Sensors and BNC cables, capable of withstanding temperatures until 250 degrees F (120 Cº)

Specifications overview RAS – Remote Access Sensors

Remote Access Sensors Kit:

The Remote Access Sensors are supplied together with everything you need to permanently mount them into your bearings:

- BNC-to-BNC cable

- Abrade tool

- CB911 Solvent Wipe

- CB 200 Acrylic Adhesive

- Wooden stick to apply adhesive

- Click Bond piece

- Acoustic Isolation Sleeve

- Mounting Instructions

- Switch Box (optional)

How to Install

Installing the UE Systems Remote Access Sensors and Switch Boxes is really simple and easy:

- Use the included Click-Bond Mounting Stud Kit which comes with a solvent wipe, an acrylic adhesive and 2 x Click Bond units which will allow you to easily glue the stud to the testing point.

- Then simply thread the RAS onto the stud and connect the cables.

- One end of the BNC-to-BNC cable connects to the RAS and the other end goes into a Remote Access Module (RAM). We have standard cables with different lengths and these can even have customized lengths when needed.

- When you need to test, just plug your Ultraprobe into the Remote Access Module (RAM) and perform your inspection as usual.

Optionally you can make use of a Switch Box:

- Run multiple BNC-to-BNC cables into the switch box and a splitter will lead them to one cable only.

- Attach the RAM to this cable, plug your Ultraprobe to the RAM and inspect 4 to 8 test points simply by switching from one channel to the other.

What you will need:

- UE Remote Access Module (RAM) adaptor enabling the Ultraprobe 9000, 10,000 or 15,000 to read data from the Remote Access Sensor (RAS). The RAM is included with the Ultaprobe 10,000 and 15,000.

- BNC-to-BNC Cable, to establish a connection between the Remote Access Sensor and the Remote Access Module. Available in the following standard dimensions: 3 feet (0.9 meters); 4 feet (1.2 meters); 15 feet (4.5 meters); 25 feet (7.6 meters); 50 feet (15.2 meters); 75 feet (22.8 meters). UE Systems might also create customized cables with different dimensions than the standard ones, at request.

- Click-Bond Mounting Stud Kit, to permanently attach the RAS to the test point. The Kit includes:

• Abrade tool

• CB911 Solvent Wipe – removes oil, grease wax and dirt from the surface to be adhesive bonded

• CB 200 Acrylic Adhesive

• Wooden stick to apply adhesive

• 2 x Click Bond pieces

• Mounting Instructions

It’s that easy!

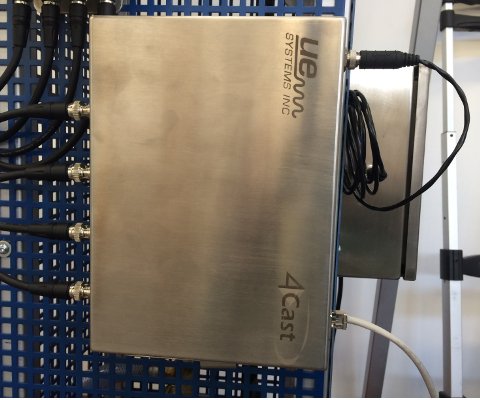

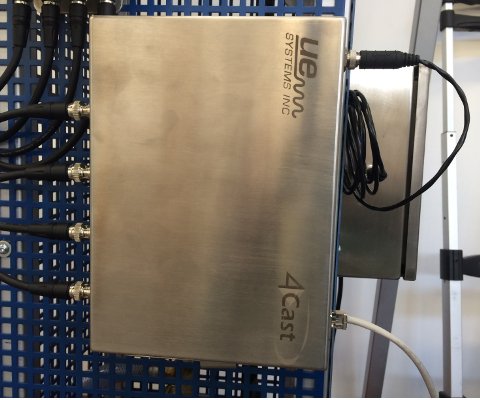

4Cast

UE Systems 4Cast – a 24/7 Ultrasonic Monitoring System

- Smart alert system

- Records data and sounds

- Send data and files to DMS software

- Setup different alarm levels

- Ethernet connection

- Highly flexible

Save time, save your bearings and improve plant reliability: review bearing information from the convenience of your office. Monitor bearing condition 24/7 and tell 4Cast when to send a report.

4Cast is a smart alert system that records data and sounds continuously, issues alarms, sends data and sound samples to specialized software for analysis and reporting.

Data along with sound samples can be reviewed and analyzed to determine the condition of a bearing just before, during and after a change in alarm status. This provides important information to help understand what happened and when.

24/7 Monitoring

Permanently installed transducers continuously monitor bearing condition 24 hours a day, 7 days a week. All data is stored locally. Should a change in condition occur and a pre-established alarm level is entered, the system, via the plant’s Ethernet will issue an alarm notification, enter data and sound samples into UE Systems DMS data management system until the alarm condition has been reversed.

Flexibility

The 4Cast system is remarkably flexible. Users can schedule condition sampling by minutes, hours, days, even weeks. An alarm level can be set to note a condition change, for example 8 dB over baseline for a lack of lubrication alarm.

Once an alarm is triggered, the user can set the number of readings prior to, during and after the alarm for analysis. The system will also send an immediate text or email to alert users of the point where an alarm was found.

Customize your report intervals

Data and sound recording transfer rates are customizable so that while the data are routinely recorded on the 4Cast box, a report containing only the latest information will be sent to Ultratrend DMS (UE Systems data management analysis and reporting program). Reporting frequency can be set by the user (for example, once a week, month or year).

Set your alarm levels

Alarm levels can be set to provide a low alarm and a high alarm.

Analyze how and why the alarm went off:

- When a set alarm level is reached or exceeded, the system will send previously logged data and recorded sounds directly to Ultratrend DMS for review.

- After an alarm has been restored, all data and sound recordings stored during the alarm period can be set to transfer to the computer for more detailed analysis and reporting.

Each 4Cast box monitors up to four bearings. The 4Cast works together with UE Systems Remote Access Sensors (RAS).

Specifications overview 4Cast

Weight: 4.7 lbs. (2.1 kg)

Length: 25’ (7.62 m), can be ordered up to 100 feet (30,48 m)

Ultra-Trak 750 – Bearing Condition & Lubrication Monitoring Transmitter

Sense ultrasonic amplitude changes in real-time to prevent lubrication issue and guard against unplanned downtime

- Continuously monitoring

- Senses ultrasonic amplitude changes

- Early warning of failure

- Prevent unplanned downtime

- Avoid lubrication issues

- Easily connects to exiting monitoring systems

The Ultra-Trak 750 is a continuously operating ultrasound sensor and transmitter in one that interfaces with existing plant control and monitoring systems providing real-time sensing of acoustic levels for early warning of bearing failures and lubrication issues.

Ultra-Trak 750 is ready to guard against unplanned downtime and product loss the minute it is installed. Ultra-Trak passively monitors ultrasounds produced by mechanical equipment. It can be readily connected to control and monitoring systems for data trending and alerting, thanks to its 4-20 mA current loop powered output. Ultrasound data is available in plant data historians and/or control systems for trending and analysis with other process parameters.

Housed in stainless steel, the rugged Ultra-Trak 750 is water resistant and dust proof, which means it can be externally mounted in some of the most challenging environments. Couple this with an extraordinarily wide dynamic range of 120 dB and sensitivity adjustment; this sensor is ready to meet your most demanding sensing needs. With the Ultra-Trak, you will gain continuous access to real-time data for early detection of developing mechanical and lubrication issues.

Once the system is connected and functioning properly, the Ultra-Trak 750 should be exposed to the user’s steady state source (ambient condition) of ultrasound. This ultrasonic source should represent a normally functioning bearing.

When a bearing enters the beginning stages of failure, there is an amplitude increase of from 12 to 50 times over a set baseline. Not only can the early stage of bearing failure be monitored and detected, other warning signs can also be noted such as: lack of lubrication, advanced failure and catastrophic failure.

Not only can the early stage of bearing failure be monitored and detected, other warning signs can also be noted such as: lack of lubrication, advanced failure and catastrophic failure.

The levels of change are as follows:

Lubrication failure: 8 db

Beginning stages of bearing failure: 16 db

Catastrophic failure: 35 to 50 db

It’s just that easy!

Ultra-Trak 750 Features:

- Ultrasound provides early warning of bearing faults in one simple an easy to understand value, perfect for alarming and trending.

- One sensors covers an entire bearing, no need for additional sensors on different axis.

- Continuously monitors critical machinery in real-time

- The loop powered transmitter interfaces with existing alarm, control and monitoring systems.

- Detects mechanical faults and provides early warning of bearing and gear faults.

- Prevents lubrication issues with the detection of lack of lubrication and prevents over-lubrication.

Specifications overview Ultra-Trak 750 – Bearing Condition & Lubrication Monitoring Transmitter

4-20 mA proportional to ultrasound signal detected

ECM-586

ECM 586 (Electric Cabinet Monitoring System)- Prevent injury from Arc Flash & reduce unplanned downtime

- Continuously Monitor – 24/7

- Detects electrical failures

- Arcing, tracking and corona

- Monitor any enclosed cabinet

- Alarm for potential failure conditions

- Prevent Arc Flash incidents

The UE-ECM 586 continuously monitors enclosed electrical equipment for the onset of corona, tracking and arcing. Utilizing a 0-10 VDC or a 4-20 mA output proportional to the received signal and a heterodyned output, it will warn in real-time as soon as any of these conditions occur.

How it works

Corona, Tracking and Arcing generate ions. The ionization process generates ultrasonic emissions that are sensed by the ECM 586.

Set a threshold level for ultrasounds that exceed ambient noise levels to signal an alarm. It’s that simple. In addition you can use the heterodyned output to record the event once ultrasound levels exceed the threshold level.

The Risks

Corona exists above 1000 Volts, arcing can occur at any voltage, low medium or high. Tracking can exist at medium or high voltages.

Any one of these conditions can lead to flash over and failure if left unattended. The ECM 586 can alert operators of the presence of these conditions to prevent equipment outage and save money.

Corona, arcing and tracking can also produce an arc flash event. Arc flash kills and burns thousands of people a year. The tragedy of an operator being seriously injured can be avoided by letting the ECM 586 warn of these conditions.

Unique Features

The ECM 586 comes with an adjustable threshold level control. There are three outputs for your convenience: 4-20 mA, 0-10 VDC and Heterodyned (demodulated).

The heterodyned output enables users to determine the cause of an elevated ultrasound level and record events through a typical audio recording device (MP3 recorder, computer, etc.).

The ECM-586 can detect electrical failures before they cause a serious accident

ECM 586 – Electric Cabinet Monitoring System

- Output: heterodyned 4-20 mA proportional to ultrasound signal detected

- Threshold setting

- Easy installation

- Comprehensive instruction/installation manual

Specifications overview ECM-586

UCA-586

The UCA-586 sensor is economically priced and is specifically designed for contact applications.

- Continuously monitor – 24/7

- Economically priced

- Bearing failure warning

- Cavitation warning

- Flow/No-Flow warning

- Valve by-pass

The Ultrasonic Condition Alert 586 (high frequency vibration transducer) constantly monitors changes in ultrasonic emissions produced by operating equipment and fluid flows.

It has a broad range of applications since practically anything that produces ultrasound can be monitored.

Applications include:

- Bearing Failure Warning

- Cavitation Warning

- Flow/No-Flow Warning

- Valve By-Pass

How The UCA-586 Works

The Ultrasonic Condition Alert senses a narrow range of high frequency vibrations. As a change in amplitude occurs, the event is noted as either an increase or decrease in voltage. This change is noted through either a 4-20 mA or 0-10 VDC output, which is directly proportional to the received signal.

An Ultrasonic Condition Alert can monitor for an increase in amplitude, a decrease in amplitude or may even be set up to “count” ultrasonic events.

Additional Applications

- Onset of rubbing conditions

- Lubrication starvation warning

- Power disruption alarm

- Solids flow monitoring

- Safety valve, rupture disc monitoring

- Screw compressor bearing monitoring

- Air handling/fan bearing monitoring

- Valve blockage

Some examples of possible applications:

- Highly viscous fluid flows through pipes. Small metal balls are used to separate the liquid and to act as a sound source. Monitoring the sounds of the metal balls as they move against the pipe indicates fluid flow. A drop in sound level indicates disruption of flow.

- Groove Counting. A machine cuts 21 groves in an armature. The armature is spun 360° creating a click for each grove. With sensor contacting the armature, the instrument counts the clicks. An incorrect count is noted in a control panel.

- A paper mill monitors a critical valve. In only specific situations is the valve to be opened. Should a valve leak, an alarm is activated.

- A food producer automatically washes large tanks with an internal spray wand. A sensor mounted on the outer wall detects the spray of water as it hits the interior wall. A localized indicator signals a ” no-wash” condition.

- An Electric utility has sensors affixed to cooling and feedwater boiler pumps to detect the onset of destructive cavitation. As air bubbles are compressed in these pumps, they burst producing a very distinctive ultrasound. Once a baseline is set cavitation is indicated by an increase in ultrasound amplitude.

- Screw Compressors: Bearings are monitored for the onset of the failure mode in compressors used for refrigeration. An increase of 10-50 times over a baseline in a monitored ultrasonic frequency is the earliest indicator of bearing failure according to NASA research.

- Fan Bearings: enclosed buildings must have ventilated air move through at a set cfm (cubic feet per minute). Should a fan bearing fail, the air quality in the building can be negatively effected. Monitors are set to alarm should a bearing enter the failure mode.

- Cooling Fan bearings in a UPS (uninterruptible power supply) for a computer room. Should the fans fail, the computers can overheat and fail. These monitors relay an alarm to a control panel.

- Dynamometers are used to simulate driving conditions in an automotive test facility. The bearings are critical for accurate results in the testing. Should a bearing become faulty, the readings of a particular test can be incorrect. These bearings are ultrasonically monitored to indicate the earliest onset of bearing failure.

- Landing gear in a test lab is used to provide information about various mechanical processes related to this type of landing gear. Sensors are mounted on the bearings of this gear and set alarm should the bearing begin to fail.

The EMC-586 is an economically priced sensor that can be used for multiple contact applications.

Technical Features

Each UCA-586 comes with an adjustable sensitivity and an adjustable threshold level. In addition, each UCA-586 can be configured to provide a demodulated or “heterodyned” output through UE Systems exclusive Ultratrend.

Ultratrend is an advanced ultrasonic filtration process that provides accurate signal detection and sound wave translation. This demodulated output is ideally suited for spectral analysis and can be connected to a computer or vibration analyzer as well as a recording device, speaker or headphone.

Every UCA-586 comes complete with transducer, epoxy mountable threaded fittings, cable, LED local alarm indicator, local LED power indicator, sensitivity adjust, threshold adjust and output cable with 4-20 mA, 0-10VDC, open collector alarm and ultrasound demodulated signal termination capability.

Threshold Set Point

The Threshold Set Point is the “Alarm Trigger”. This will be used to activate whatever type of alarm is selected.

The UCA-586 may be wired to trigger an alarm if the amplitude increases, such as for bearing failure or valve leakage. Or it may be wired to alarm should the amplitude decrease, such as in flow disruption.

Sensitivity Range Set Point

The Sensitivity Set Point sets the unit to “hear” only the relevant ultrasonic signals. This is accomplished by moving a 40 dB monitoring range anywhere along the UCA-586’s 100 dB dynamic range.

UCA 586 – Ultrasonic Condition Alert System

- Detection Frequency: 25-50 kHz

- Power Supply Requirements: 20-30 VDC 200 mA

- Oil resistant

- Operating Temperature: 32°F – 140°F (0-60° C)

- Transducer Cable: RF Shielded, Standard 9,8 ft. (3 meters)

- Glue & Stub kit for easy installation

- Comprehensive instruction/installation manual

Specifications overview UCA-586

Transfer Function: dB/mA DC

Scale: 1 mA DC = 2.5 dB input level

Dynamic Measurement Range: 40 dB (set anywhere along the 100 dB input range)

0-10 DC V Linear Output Transfer Function: dB/VDC

Scale: 1 VDC = 4 dB input level

Dynamic Measurement Range: 40 dB (set anywhere along the 100 dB input range)

Threshold Level: Adjustable over the output range. Alarm output stops con-ducting when input level exceeds the threshold level (set point)

3 dB bandwidth approx. 6 kHz

Can be easily mounted in standard NEMA enclosures

Dimensions: Dia: 1.0” (2.54 cm) Length: 2.4” (6.1 cm)

Thread: (female) 10/32