INSTRUMENTATION

BCS-211

The ADCATROL BCS-211 controller is part of the dissolved solids (TDS) control system used in steam boilers. This system is composed of a SPS series conductivity probe, a BCS-211 controller, a VPC series blowdown valve and, in case of need, a UC-820 universal process controller for PID control.

SUPPLY VOLTAGES

230 V AC +/- 15%, 50/60 Hz

DIMENSIONS

106 x 51 x 112 mm

IP RATING

IP 40

CONDUCTIVITY RANGE

BCS-211 – 0 to 10000 µS/cm

BCS-211B – 0 to 1000 µS/cm

PCS1

The PCS1 series pressure transmitters are suitable for all industrial applications, especially in severe conditions where high temperatures, pressure peaks and high levels of shock and vibration are present. They are extremely robust and reliable, thanks to their state of the art SMD electronics and compact all stainless steel construction.

SIZES AND CONNECTIONS

Male threaded

ISO 228 G 1/4”

PRESSURE RANGES

0 to 6 / 0 to 10 / 0 to 16

0 to 25 / 0 to 40 / 0 to 100

0 to 250 / 0 to 400 / 0 to 600

ACCURACY

< ±0,5% FS

RESPONSE TIME

< 1 ms

OUTPUT

4 to 20 mA (2-wire)

IP RATING

IP 65 / IP 67

SPS-33

The ADCATROL SPS-33 conductivity probe is used to measure the conductivity (TDS) of the superheated water of boilers or condensate. The probe is used in conjunction with an ADCATROL BCS-211 controller and VPC series blowdown valve.

SIZES AND CONNECTIONS

Male threaded ISO 7 R 1/2”

MAX. OPERATING PRESSURE

32 bar

MAX. OPERATING TEMPERATURE

239 ºC

IP RATING

IP 65

SPS-21

The ADCATROL SPS-21 conductivity probe is used to measure the conductivity (TDS) of the superheated water of boilers or condensate. The probe is used in conjunction with an ADCATROL BCS-211 controller and VPC series blowdown valve.

SIZES AND CONNECTIONS

Male threaded ISO 7 R 1/2”

MAX. OPERATING PRESSURE

32 bar

MAX. OPERATING TEMPERATURE

239 ºC

IP RATING

IP 65

TRPT1

The TRPT1 Pt100 resistance temperature sensors are specially designed for general industrial use. The sensing element is an RTD three wire device according to EN 60751 Class A. The sensor consists of a probe, a connection head and a measurement insert. The supply lines to the measurement insert are insulated from each other and from the probe tube with a ceramic insulator. The sensor can be connected directly to a temperature indicator or controller that has a three-wire Pt100 input.

SIZES AND CONNECTIONS

Male threaded ISO 7 R 1/2”

OUTPUT

3-wire RTD or 4 to 20 mA (2-wire)

IP RATING

IP 66 (KNE enclosure)

SV32

3/2 way solenoid valves are available as single station units and they are designed for use with compressed air, mainly applied where on/ off control is required with pneumatic actuators.

MATERIAL

Alluminium alloy

SIZES AND CONNECTIONS

Female threaded

ISO 7 Rp 1/4”

MAX. OPERATING PRESSURE

8 bar

SUPPLY VOLTAGES

220 V AC

110 V AC

24 V DC

24 V AC

IP RATING

IP 65

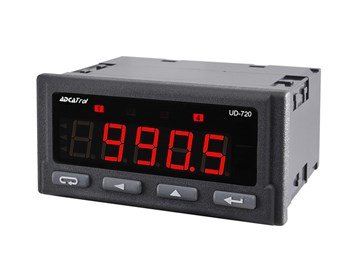

UD-720

The UD-720 is a programmable digital panel display used for the measurement of standard sensor and analog signals applied in automation. It is ideally suited for use with our range of instrumentation such as pressure transmitters, temperature probes and TDS controllers.

SUPPLY VOLTAGES

24 V AC/DC

85 to 253 V AC/DC

DIMENSIONS

93 x 96 x 48 mm

IP RATING

IP 65

COMMUNICATION PROTOCOL

MODBUS RTU

UC-820

The UC-820 is a digital universal controller used in the automation of industrial processes. It is ideally suited for use with our range of instrumentation, electric and pneumatic control valves and other electrical equipment. The controller includes a set of universal type inputs for RTD, thermocouple (TC), logic (binary) and analog inputs. The controller has options for a relay, open-collector (OC) and analog outputs using the innovative SMART PID algorithm.

SUPPLY VOLTAGES

20 to 40 V AC/DC

85 to 253 V AC/DC

DIMENSIONS

101 x 48 x 96 mm

IP RATING

IP 65

COMMUNICATION PROTOCOL

MODBUS RTU

P10

The P10 air filter regulators are used to remove both solid and liquid impurities from the air and to regulate the output pressure to the required value for general purpose pneumatic systems. The filter bowl is transparent, allowing easy monitoring of the condensate level.

MATERIAL

Aluminium and polycarbonate

SIZES AND CONNECTIONS

Female threaded

ISO 7 Rp 1/4”

PC25

An instrument that converts a standard DC signal to a standard pneumatic signal, for the change-over from electrical controllers to pneumatic control valves, or from electrical measuring system to pneumatic controllers. The PC25 is a force balance device, which converts a 4…20 mA input signal into a proportional 3…15 psi (0,2…1 bar) or 6…18 psi (0,4…1,2 bar) output signal, with a respective supply pressure of 1,7 – 5 bar.

PI991

The microprocessor-controlled positioner PI991 is designed to control pneumatic valve actuators and can be operated locally or by means of control systems. The advanced diagnostic can be partially shown on the local LCD of the positioner or fully on a PC or a DCS workstation with a DTM based software (VALcare or Valve Monitor). The positioner is available with different communication protocols. This includes versions with analog setpoint (4 to 20 mA) and superimposed HARTor FoxCom signal; digital with FoxCom protocol, or fieldbus communication according to PROFIBUS-PA and FOUNDATION fieldbus H1 according to IEC 1158-2 based on FISCO. The PI991 also has the capability to control a Partial Stroke Test (PST) that offers operators a tool to identify the trouble-proof function of ESD (Emergency Shut Down) valves.

PI998

The intelligent positioner PI998 is designed to operate pneumatic valve actuators and can be operated from control systems, controllers or PC-based configuration and operation tools such as the FDT/DTMs or VALcare™. The enhanced functionalities of the PI998 Intelligent Valve Positioner enable a significant reduction in commissioning time and reduction of the total installation cost. The new device offers an improved control performance with or without external accessories such as volume boosters for optimal efficiency of your process. The modular design makes maintenance simpler, and advanced technology increases the total lifetime of the device.

PE986

The ADCATrol PE986 positioner requires an input signal of 4÷20 mA for the proportional control actuator. The positioner compares the output signal from a controller with the position feedback and varies a pneumatic output signal to the actuator accordingly. The actuator position is therefore guaranteed for any controller output signal and the effects of varying differential pressure.

TZIDC

The ADCATrol PE986 positioner requires an input signal of 4÷20 mA for the proportional control actuator. The positioner compares the output signal from a controller with the position feedback and varies a pneumatic output signal to the actuator accordingly. The actuator position is therefore guaranteed for any controller output signal and the effects of varying differential pressure.