Water Deionizer Systems

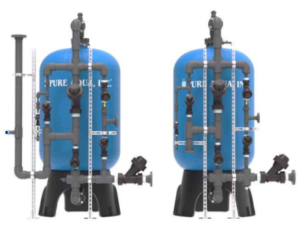

Engineered for medium-sized deionization (DI) applications, these dependable units feature the same precision electronics and performance characteristics as their large-scale counterparts, all in a smaller, using diaphragm valves package. Applications cover the full spectrum of industrial, commercial, medical, boiler feed water uses. Pure Aqua offers a wide range of IX systems and resin types for general manufacturing and industrial applications, as well as special grades of resin for critical applications such as food & beverage, nitrate removal, arsenic removal, healthcare, biopharmaceutical and microelectronics.

Advantages of choosing a Pure Aqua Dual-Bed Deionizer include:

- Two-Bed Automatic “Package” Deionizers are available in sizes from 2-8 GPM, and at rated exchange capacities: of 40,000 to 100,000 grains. These systems are fully-assembled, with all wiring and tubing completed requiring minimum installation and start-up effort. Skid mounting is an option.

- Exchanger vessels are all non metallic construction, rated at 150 psi.

- Piping is Schedule 80 PVC, with solvent-welded joints, rigidly supported on unit strut channels.

- Valves-Noryl diaphragm type, pneumatically operated, with integral travel stops for flow regulation.

- Internal distributions are PP / schedule 80 PVC and radial lateral design.

- The provided cation resin is a high capacity strong acid, bead-form, conventional gel polystyrene sulfonated exchange resin which is shipped in the hydrogen form ready for immediate use. Resin capacity information is based on 6 lbs. of HCL per cu. ft. of exchange resin. The provided anion is a high capacity strong base, type 2, bead form, conventional gel exchange resin which is shipped in the chloride form for maximum storage life. Resin capacity information is based on 6 lbs. of NaOH per cu. ft. of exchange resin.

- Optional stainless steel liquid filled pressure gauges, sample valves, flow indicator on water inlet, and inlet pressure reducing valve.

Pre-Treatment Systems: | Post-Treatment Systems | Other Systems |

|

|

|

Model No. |

| Service Flow Rate GPM |

| Mineral | Resin Quantity (ft)3 |

| |||

Cont. | Peak | BW | Cation | Anion | |||||

DM14-Q-FRP | 65,000 | 4 | 10 | 7.8 | 1″ | 14″ * 65″ | 3 | 3 | 800 |

DM16-Q-FRP | 80,000 | 6 | 12 | 9 | 1″ | 16″ * 65″ | 4 | 4 | 1,200 |

DM18-Q-FRP | 100,000 | 8 | 14 | 10 | 1″ | 18″ * 65″ | 5 | 5 | 1,400 |

DM21-Q-FRP | 140,000 | 12 | 18 | 15 | 1.5″ | 21″ * 65″ | 7 | 7 | 1,650 |

Standard Features: | Available Options: | |

|---|---|---|

|

|

|

The Industries and applications in which a dual-bed deionizer find use include: | |

|

|

Engineered for large-sized deionization (DI) applications, these dependable units feature precise electronics and performance characteristics, using diaphragm valves package. Applications cover the full spectrum of industrial, medical, electronics manufacturing, boiler feed water, and chemical manufacturing uses. Pure Aqua supplies a full line of standard and fully customizable dual bed deionizer systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.

Pure Aqua, Inc. is a global leading manufacturer of industrial water deionization systems designed for efficient removal of dissolved salts and minerals. These water treatment systems produce high purity water for industrial applications. We also design and manufacture a complete line of ion-selective resin deionization systems to remove selective ions such as nitrates, arsenic, silica, boron, fluoride or to meet your water quality requirements.

Advantages Of A Dual Bed Deionizers DM-6100 Series

- Two-Bed Automatic “Package” Deionizers are available in sizes from 11-43 GPM, and at rated exchange capacities of 200,000 to 800,000 grains. These systems are fully-assembled, with all wiring and tubing completed requiring minimum installation and start-up effort. Skid mounting is an option.

- Exchanger’s vessels are all nonmetallic construction, rated at 150 psi.

- Piping is Schedule 80 PVC, with solvent-welded joints, rigidly supported on unit strut channels.

- Valves-Noryl diaphragm type, pneumatically operated, with integral travel, stops for flow regulation.

- Internal distributions are PP/schedule 80 PVC and radial lateral design.

- The provided cation resin is a high capacity strong acid, bead-form, conventional gel polystyrene sulfonated exchange resin which is shipped in the hydrogen form ready for immediate use. Resin capacity information is based on 6 lbs. of HCL per cu. ft. of exchange resin. The provided anion is a high capacity strong base, type 2, bead form, conventional gel exchange resin which is shipped in the chloride form for maximum storage life. Resin capacity information is based on 6 lbs. of NaOH per cu. ft. of exchange resin.

- Optional stainless steel liquid filled pressure gauges, sample valves, flow indicator on water inlet, and inlet pressure reducing valve.

Pre-Treatment Systems: | Post-Treatment Systems | Other Systems |

|

|

|

Model # | Nominal | Service Flow |

|

| Resin Quantity (ft)3 | ||

|---|---|---|---|---|---|---|---|

Cont. | Peak | Cation | Anion | ||||

DM24-Q-FRP | 200,000 | 11 | 35 | 2” | 24”x72” | 10 | 10 |

DM30-Q-FRP | 300,000 | 17 | 50 | 2” | 30”x72” | 15 | 15 |

DM36-Q-FRP | 400,000 | 25 | 70 | 2” | 36”x72” | 20 | 20 |

DM42-Q-FRP | 600,000 | 34 | 100 | 3” | 42“x72” | 30 | 30 |

DM48-Q-FRP | 800,000 | 43 | 135 | 3” | 48”x72” | 40 | 40 |

Standard Features: | Available Options: | ||

|---|---|---|---|

|

|

| |

Manufacturing | Laboratories | Commercial |

|---|---|---|

|

|

|

Due to the requirements of high quality water in many industries, Pure Aqua has developed the RC-6500 Series. The Pure Aqua RC-6500 Series ion exchange filters provide high quality water in low volumes for specialized uses.

The cartridges have been developed in response to the requirements for deionized water in many industries. These high-capacity semi conductor grade resin cartridges are ideal for use in pharmaceutical and medical, laboratories, cosmetic and circuit board and printing applications.

The cartridges are available in three sizes, flow rates and capacities, they are convenient and cost effective for many applications where low levels of total organic carbon (TOC) and total dissolved solids are required.

They are manufactured using resin that has been subjected to additional post production steps to minimize the total organic carbon (TOC) level. The Softening or Deionizing Cartridges are designed for deionizing water, and all materials and construction are FDA Compliant.

Model | RCS Models | RCD Models | ||||||

|---|---|---|---|---|---|---|---|---|

(Softening Ion Exchange Systems) | (Deionizing Ion Exchange Systems) | |||||||

RCS-10 | RCS-20 | RCS-10BB | RCS-20BB | RCD-10 | RCD-20 | RCD-10BB | RCD-20BB | |

Housing Model | H-1034-BL | H-2034-BL | BBH-1010 | BBH-2015 | H-1034-BL | H-2034-BL | BBH-1010 | BBH-2015 |

Housing Size | 2.5″x10″ | 2.5″x20″ | 4.5″x10″ | 4.5″x20″ | 2.5″x10″ | 2.5″x20″ | 4.5″x10″ | 4.5″x20″ |

Cartridge Model | SFT-10 | SFT-20 | SFT-10-B | SFT-20-B | DI-10 | DI-20 | DI-10-B | DI-20-B |

Cartridge Size | 2.5″x10″ | 2.5″x20″ | 4.5″x10″ | 4.5″x20″ | 2.5″x10″ | 2.5″x20″ | 4.5″x10″ | 4.5″x20″ |

Capacity (Grains) | 450 | 1000 | 1500 | 3000 | 270 | 600 | 925 | 1850 |

Flow Rage (GPM) | 0.13 | 0.5 | 0.8 | 1.25 | 0.13 | 0.5 | 0.8 | 1.25 |

Max. Pressure Inlet (Psi) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

Temperature Range (°F) | 45 to 100 | 45 to 100 | 45 to 100 | 45 to 100 | 45 to 100 | 45 to 100 | 45 to 100 | 45 to 100 |

| Top Quality Deionizer Resins: | Attractive Functional Design: | Corrosion Proof Housing: |

|

|

|

The ideal applications for Pure Aqua Ion Exchance Cartridges Include: | ||

|

|

|

Ion Exchange can be defined as a reversible exchange of ions between a solid (resin) and a liquid containing dissolved ions. Mineral salts are comprised of cations and anions. Since deionization requires the removal of all ions, both the negatively charged anions and positively charged cations, minerals capable of attracting both are required. These materials are known as anion and cation exchange resins.

Pure Aqua Deionizers are fixed bed systems in which ion exchange resins are contained in pressure vessels. The water is then forced through the resin. After a service run, the resin becomes exhausted and unable to remove additional ions so it must be regenerated with strong acid and base solutions to restore its ion exchange capacity.

Model # | Nominal Capacity | Service Flow Rate (GPM) | Pipe Size | Mineral Tank Size | Resin Qty. | ||

|---|---|---|---|---|---|---|---|

Average | Peak | Cation | Anion | ||||

MB18-PVN/m9060 | 62,000 | 18 | 27 | 2″ | 18″x108″ | 2.5 | 3 |

MB24-PVN/M9065 | 112,000 | 31 | 47 | 2″ | 24″x108″ | 4.5 | 5.5 |

MB30-PVN/m9070 | 170,000 | 50 | 75 | 2″ | 30″x108″ | 7 | 8.5 |

MB36-PVN/M9075 | 250,000 | 70 | 105 | 2″ | 36″x108″ | 10 | 12.25 |

MB42-PVN/M9080 | 350,000 | 100 | 145 | 3″ | 42″x108″ | 14 | 17.25 |

MB48-PVN/M9085 | 450,000 | 125 | 190 | 3″ | 48″x108″ | 18 | 22.25 |

Standard Features: | Available Options: |

|

|

Pure Aqua Deionizers are often used in applications requiring very high water quality, usually as polishers after reverse osmosis. Many industries use DI systems: | |||

|

|

|

|