Ultrasonic Testing Instruments

Ultrasonic Thickness Gauge NOVOTEST UT-1M

Ultrasonic Thickness Gauge NOVOTEST UT-1M is used for operational non-destructive testing of the thickness of products with one-way access, at the moment this method is the most common in the world for solving such tasks.

Ultrasonic Thickness Gauge NOVOTEST UT-1M is used for operational non-destructive testing of the thickness of products with one-way access, at the moment this method is the most common in the world for solving such tasks.

The method is based on the property of materials to conduct ultrasound, ultrasonic wawes are excited with the piezoceramic plate in the transducer and penetrates into the material through the couplant, then reflected from the bottom surface of the tested sample, and returns to the transducer. Based on the obtained sound transit time in the material, the device calculates the thickness in accordance with the velocity of propagation of ultrasonic waves in the test sample. The thickness value is displayed on the device’s display, the measurement process takes about 1 second.

The main advantages of the Ultrasonic Thickness Gauge NOVOTEST UT-1M:

WIDE RAGE OF MEASUREMENTS

To measure products in a wide range with one transducer, unlike most similar devices, the Ultrasonic Thickness Gauge NOVOTEST UT-1M has a gain control function, which allows operator, for example, with a 5 MHz transducer, to measure steel products in the range from 0.5 to 500 mm and more.

B-SCAN AND AUTOMATIC DEFECT ALARM FUNCTION

To visualize the product profile, if necessary not only point measurement, but also scanning, a B-scan is implemented in the device, which allows the user to visually see thinning and thickening of the wall of the testing object.

Also, for ease of use, the device has an automatic defect alarm function, its meaning is that the operator can select boundary thickness values (minimum and maximum) when crossing the values of which the device will signal through the speaker, and also give a visual signal.

ARCHIVE OF PROBES AND MEASUREMENTS

Ultrasonic Thickness Gauge NOVOTEST UT-1M has the ability to save transducer’s parameters (delay line, V-correction, etc.), and also has reference values for the wave velocities of many often measured materials stored in devices’s memory, which allows the user to blindly (without reference data and a sample material for calculating speed) to measure various products with one-way access.

PRACTICAL HOUSING

Ultrasonic Thickness Gauge NOVOTEST UT-1M is made in an ergonomic shockproof case, the silicone cover of which prevents the device from malfunctioning in case of a dropped down to floor or ground. Also, the device can be used in extreme climatic conditions, the temperature range of operating conditions is from -20 to +40 ° С.

The device allows user to record the measurement results in the archive of the device, and subsequently transfer them to a PC using special software.

- Wide range of measuring thicknesses

- Convenience and ease in operation

- Minimum number of controls

- Select the type of probe through single button

- Preset velocity of ultrasound

- Graphical display with backlight

- Compensation of probe delay

- Control of the batteries

- Mapping the presence of acoustic coupling on the graphic display

- Fixation of the last measurement result in the removal of the transducer surface

| Measuring thicknesses range , mm:

| 0.8 … 300 or more

|

| Probe dimensions, mm:

|

|

| Diameter of probe contact area, mm:

|

|

| Size of plate:

|

|

| Setting range of the ultrasonic velocity, m / s | 1000-17000 |

| Discrete readings on the digital indicator, mm | 0.1 |

| Response time, with no more than | 1 |

| Basic measurement accuracy, mm | ± (0,01 T+0.05) |

| Echo-Echo mode (through coating measuring), max thickness of coating, mm | 1 |

| Standards | ASTM E797 |

| Storage of measurement results | 256 |

| Overall dimensions, mm | 120x60x25 |

| Operating temperature range, ° C | -5 to +40 |

| Power supply | 2 AA batteries |

| Time of continuous work hours, not less, h | 10 |

| Weight of electronic unit with battery, no more, kg | 0.2 |

- Couplant

- UT-probes

- Calibration blocks

- Electronic unit Ultrasonic Thickness Gauge

- Transducer (probe) – 1 pc

- AA batteries – 2 pcs

- Charger

- Cable for PC

- Operating manual

- Case

Ultrasonic Thickness Gauge NOVOTEST UT-1M-IP

Ultrasonic Thickness Gauge NOVOTEST UT-1M-IP is a special version of ultrasonic thickness gauge, it is designed to measure the thickness of various materials and products for one-way access in difficult climatic conditions – in dusty rooms, in high humidity, in the rain – when the use of a conventional ultrasonic thickness gauge is impossible.

It is used to control the thickness of materials such as glass, metals and alloys, polymers, plastic and many others. Objects can be pipes, rolled products, structures, products and parts for various purposes and shapes.

The main advantages of the Ultrasonic Thickness Gauge NOVOTEST UT-1M-IP:

INCREASED DUST AND MOISTURE RESISTANCE

Unique protection against dust and moisture – by default, the device is delivered with a degree of dust and moisture protection IP65 according to DIN 40050. When ordering, versions of a thickness gauge with moisture protection up to IP67 are available (immersion in water is allowed).

UNPRECEDENTED AUTONOMY OF THE DEVICE

Due to the features of circuitry and operating modes – the continuous operation time of the device in practice reaches 200 hours. What makes the device ideal for field conditions in the absence of power supply.

WIDE RANGE OF MEASURING

Ultrasonic Thickness Gauge NOVOTEST UT-1M-IP can be equipped with various types of transducers, however, the device has the ability to advanced settings of transducers (gain, path, V-correction, etc.), which allows the user to get the maximum operation range with one transducer, in practice, the operating range of the 5 MHz probe reaches from 0.5 to 500 mm.

LIBRARY OF MATERIALS AND PROBES

The device has a library of velocities of basic materials, as well as an archive of transducers, which allows the operator to take measurements at various objects without additional reference information and complicated setup. Also, the user can independently replenish the settings archive.

TRANSFERRING DATA TO PC

Device has special water-dustproof connector and special cable in set.

Using a special software for PC, it is possible to transfer the saved measurement results to PC for further processing.

- Unique protection from dust and moisture, previously not available in the market of ultrasonic thickness gauges of general purpose. By default the device comes with a degree of dust-moisture protection IP65. This protection degree can be increased up to IP67 (submerged in water) at order;

- Unprecedented autonomy of the device – increased up to 200 hours continuous operation time of the thickness gauge;

- Special rubber lining on the side surfaces of the casing facilitates the convenient retention of the thickness gauge in the user’s hand;

- Device has light weight and dimensions, in comparison with similar protected thickness gauges;

- Saved data can be transmit to PC;

- Material selection and automatic setting of ultrasound velocity;

- Large graphic display of high contrast and backlight;

- Display of measured thickness in mm and inches;

- Convenient menu in the device;

- Wide choice of UT probes with preset settings in the device;

- Modes of statistical processing of measurements;

- Ability to restore factory calibrations;

- Ability to adjust all parameters of the acoustic path;

- Ability of further adjusting the user gain directly from the measurement mode;

- Wide range of testing;

- Mode of audible and visual alarm when leaving the established ranges.

| Measuring thicknesses range , mm:

| 0.8 … 500 or more

|

| Probe dimensions, mm:

|

|

| Diameter of probe contact area, mm:

|

|

| Size of plate:

|

|

| Setting range of the ultrasonic velocity, m / s | 1000-17000 |

| Discrete readings on the digital indicator, mm | 0.1 |

| Response time, with no more than | 1 |

| Basic measurement accuracy, mm | ± (0,01 T+/- 0.05) |

| Echo-Echo mode (through coating measuring), max thickness of coating, mm | 1 |

| Standards | ASTM E797 |

| Storage of measurement results | 256 |

| Overall dimensions, mm | 120x60x25 |

| Operating temperature range, ° C | -5 to +40 |

| Power supply | 3 AA batteries |

| Time of continuous work hours, not less, h | up to 200 |

| Weight of electronic unit with battery, no more, kg | 0.2 |

- Couplant

- UT-probes

- Calibration blocks

- Electronic unit Ultrasonic Thickness Gauge

- Transducer (probe) – 1 pc

- AA batteries – 3 pcs

- Charger

- Cable for PC

- Operating manual

- Case

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST is a special version of the thickness gauge in a metal enclosure, which is designed for extreme operating conditions, when there is a possibility of the device dropping or other damage of the unit during operation. The durable aluminum bodies profile withstands high static and dynamic compression loads, which allows the operator to use the device “carelessly”.

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST is designed to measure the thickness of products with low attenuation of ultrasonic vibrations, with one-way access to them during their manufacture and operation.

Some advantages of Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST:

WIDE RANGE OF THICKNESS OF TESTING PRODUCTS

Same as other ultrasonic thickness gauges TM “NOVOTEST”, Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST allows user to measure the thickness of products in a wide range with a minimum set of transducers, this is achieved thanks to the advanced settings of the device (amplification of two stages, V-correction, etc.)

UNIVERSAL TRANSDUCERS

Any dual-element probes can be connected and configured to the device by cables with standard connectors. What makes Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST universal to use, and does not limit users in choosing a probes for operation.

DISPLAY THE PRODUCT PROFILE WHEN SCAN

The device has a scanning mode of the product in the mode of a B-scan, which allows user to visualize thinning and thickening of the wall like a graph on the display of the device. This allows the user to see the product profile, which simplifies the operator’s work. Additionally, there is an alarm function for exceeding the maximum and minimum thickness limits that are pre-set by the operator.

THICKNESS SAMPLE FOR ADJUSTING THE DELAY OF THE TRANSDUCER

Like other ultrasonic thickness gauges TM “NOVOTEST”, the Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST has a thickness sample mounted on the device’s body, which allows the user to quickly set “0” (calculate the delay in the probe) when changing the transducers or the operating conditions of the device.

The device has a memory where the reference book of the propagation velocities of the most common materials is stored, also the device allows user to save the settings of the transducers and measurement results, which can be stored both in the device and transferred to a PC using special software that is supplied with the standard Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST set.

- Unique additional protection of metal housing;

- Saved data can be transmit to PC;

- Material selection and automatic setting of ultrasound velocity;

- Large graphic display of high contrast and backlight;

- Display of measured thickness in mm and inches;

- Convenient menu in the device;

- Wide choice of UT probes with preset settings in the device;

- Modes of statistical processing of measurements;

- Ability to restore factory calibrations;

- Ability to adjust all parameters of the acoustic path;

- Ability of further adjusting the user gain directly from the measurement mode;

- Wide range of testing;

- Mode of audible and visual alarm when break the preset ranges.

| Measuring thicknesses range , mm:

| 0.5 … 500 or more

|

| Probe dimensions, mm:

|

|

| Diameter of probe contact area, mm:

|

|

| Size of plate:

|

|

| Setting range of the ultrasonic velocity, m / s | 1000-9999 |

| Discrete readings on the digital indicator, mm | 0.1 |

| Response time, with no more than | 1 |

| Basic measurement accuracy, mm | ± (0,01 T+/- 0.05) |

| Echo-Echo mode (through coating measuring), max thickness of coating, mm | 1 |

| Standards | ASTM E797 |

| Storage of measurement results | 256 |

| Overall dimensions, mm | 120x60x25 |

| Operating temperature range, ° C | -5 to +40 |

| Power supply | 2 AA batteries |

| Time of continuous work hours, not less, h | 10 |

| Weight of electronic unit with battery, no more, kg | 0.2 |

- Couplant

- UT-probes

- Calibration blocks

- Electronic unit Ultrasonic Thickness Gauge UT-1M-ST

- Transducer (probe) – 1 pc

- AA batteries – 2 pcs

- Charger

- Cables

- Operating manual

- Case

Reference Blocks

V1 and V2 – are common used reference (calibration) blocks for UT testing.

Reference Block V1 allows to:

- determine the insertion point of ultrasonic oscillations and distance from the piezoceramic plate to the probe housing with accuracy ± 0,5mm;

- define the angle of input of the ultrasonic oscillations with accuracy ±1 angle degree;

- define the uncontrollable (dead) zone (for steel) straight beam ultrasonic piezoelectric transducers;

- determine the linearity of ultrasonic scanning horizontally;

- configure the speed and sensitivity of the scan of straight beam, angle beam and dual element piezoelectric transducers.

Reference Block V2 allows to:

- calibrate the scanning of flaw detectors through the expansion velocity of ultrasonic waves, working with straight beam piezoelectric transducers;

- calibrate the scanning of flaw detectors through the expansion velocity of ultrasonic waves, working with angle beam piezoelectric transducers;

- set conditional sensitivity of ultrasonic flaw detectors with straight beam and angle beam piezoelectric transducers;

- determine the output point of ultrasonic oscillations and distance from the piezoceramic plate to the probe housing;

- define the angle of input of the ultrasonic oscillations into steel.

But there are available other types of blocks in accordance to different standards (ISO, DIN, etc.). If need UT or PAUT blocks of other standards, please send enquiry.

- High quality

- Competitive price

Specifications of Reference Block V1

- Sample is made from low carbon fine-grained steel with a small damping coefficient.

- Expansion velocity of longitudinal ultrasonic oscillations in the calibration block at the frequency 5.0 MHz and at the temperature of 20(± 5) °C is 5920(± 30) m/s.

- Expansion velocity of shear (transversal waves) ultrasonic oscillations in the insertion material into calibration block at the frequency 5.0 MHz and at the temperature +20(± 5) °C is 2670(±100) m/s.

- The geometrical dimensions of the sample corresponds to ISO 2400, DIN 54120, BS 2704.

Specifications of Reference Block V2

- Expansion velocity of longitudinal ultrasonic oscillations in the calibration block at the frequency 5.0 MHz and at the temperature 20(± 5) °C is 5920(± 30) m/s.

- Expansion velocity of transversal ultrasonic oscillations in the insertion material into calibration block at the frequency 5.0 MHz and at the temperature of 20(± 5) °C is 3255(±15) m/s.

- Reference Block V1

- Reference Block V2

- Certificates

- Reference Block

- Package

Ultrasonic Flaw Detector NOVOTEST UD3701

The Ultrasonic Flaw Detector NOVOTEST UD3701 is designed to detect internal defects, such as discontinuities and heterogeneities of materials in products and welds, determine coordinates and evaluate defect parameters, measure thickness and the velocity of propagation and attenuation of ultrasonic waves in the materials (metals, plastics, glass and etc.), the search for places of corrosion, cracks, internal delamination and other defects.

Ultrasonic Flaw Detector NOVOTEST UD3701 is a universal, powerful, functional, ergonomic and reliable device for solving tasks of ultrasonic flaw detection both in the laboratory and in the field.

The main advantages of the Ultrasonic Flaw Detector NOVOTEST UD3701 include:

BRIGHT TFT TOUCHSCREEN DISPLAY

Thanks to the multi-touch screen, the operator can easily move the gates and set the scan without using buttons and encoders. All functions for setting up and controlling the device can be carried out both through the touchscreen and in the classic way – using the keyboard. The TFT display of the device is very bright and contrasting with a resolution of 800×480 pixels, which allows users to get clear picture of the signals on the screen.

AVAILABILITY OF MANY USEFULL FUNCTIONS

The envelope mode of the signal allows user to detect the maximum of signals, as well as get the envelope of the signal curve when scanning the reflector.

Auto zoom – the electronic magnifier mode allows operator to focus the scan on the selected gate by clicking just one key.

Fill function – designed to improve the perception of the image on the screen of the device. The A-Scan signal is filled with the color matching the color of the signal line.

Simulation of a measurement from a stored record in the instrument memory.

The presence of movable blocks of output of measured values, which allows the operator to arrange blocks of parameters at any place of the A-scan.

DAC & TVG

The Ultrasonic Flaw Detector NOVOTEST UD3701 has the ability to build and configure the Distance Amplitude Correction (DAC) and Time Varied Gain (TVG) functions, using up to 16 points, to estimate the size of the reflectors relative to the reference ones at different depths.

DGS CURVES

Using the DGS (Distance Gain Size) mode, the operator can configure the device according to the signal from the reference reflector, and then receive automatic calculation of equivalent reflector sizes at various depths.

COLOR SCHEMES

Ultrasonic Flaw Detector NOVOTEST UD3701 gives the operator full control over the color scheme of the device in the “FLAW DETECTOR” mode for more comfortable work. Also in the device there are two predefined color schemes: dark and light. This option allows the operator to choose the option of displaying information comfortable for the eyes both in a dark room and in bright sun.

AUTOMATIC DEFECT SIGNALING

Using two independent gates, the operator can set the boundary parameters of the amplitude or distance (time) of the signals on the scan, which will indicate the presence of defects through sound and light indications. This allows the operator to scan the object without continuous monitoring of the display, which subsequently reduces the complexity of testing.

UNIVERSALITY OF APPLICATION

The device is ideally suited for performing ultrasound diagnostics in laboratory and workshop conditions, however, if necessary, it can be used in the field. To do this, we recommend to use of a special cover that protects the device from dirt and moisture, and also allows the operator to completely free his hands and easily testing of various products directly at the facility.

PC SOFTWARE & ARCHIVE

Using special software, the device allows user to transfer to the PC a previously saved measurement archive. Also in the device it is possible to save parameters and settings of tested objects and used probes.

- Superbright, touch display with which it is comfortable to work outdoors on a sunny day;

- Automatic calculation of the delay in the probe;

- Frequency range from 0 to 10 MHz, with smooth adjustment;

- Display of a scale of scanning in microseconds and millimeters;

- The presence in the device of the operating mode of the DAC and TVG curves (up to 16 points);

- The presence in the flaw detector of the DGS control mode, with automatic calculation of the equivalent reflector zone;

- Carrying out settings both using the touch screen and by keyboard;

- The presence of movable blocks of output of measured values, so it can be located in any part of the A-scan;

- Archive of measurements, settings, probes with the ability to transfer data to a PC;

- Simulation of a measurement from a stored record in the device memory.

| Operating frequency range | from 1 to 10,0 MHz |

| Range of measured time intervals (duration of scanning) | from 6 to 1000 µs |

| Velocity range | 1000 – 9999 m / s |

| Error of measurement of time intervals | not exceed ± 0,025 µs |

| Maximum permissible error of measurement of the amplitudes of the signals at the receiver input in the range from 0 to 110 dB | not exceed ± 0,5 dB |

| Testing gain range | 125 dB |

| Averaging over the quantity of starts | from 1 to 16 |

| Range of variation of temporal sensitivity adjustment (TVG) | 40 dB |

| Number of control points TVG | 16 |

| Duration of the excitation pulse to the load | from 0,0 to 0,5 µs |

| Deviation of the amplitudes of input signals in the range from 10 to 100% of the screen height not more than | 1 dB |

| Setting a delay in the prism of the probe | from 0 to 15 µs |

| Detection of signals | positive half-wave, radio mode |

| Dimensions (W*H*L) | 140 mm x 210 mm x 55 mm |

| Weight, not more | 1,5 kg |

- Additional UT-probes

- Additional cables Lemo-Lemo

- Charger

- Bag for comfortable operating

- Calibration blocks

- Ultrasonic flaw detector

- UT-probes – 2 pcs

- Cable Lemo-Lemo – 1 pc

- Charger

- USB cable for PC connection

- Operating manual

- Case

Ultrasonic Flaw Detector NOVOTEST UD2301

An ultrasonic flaw detector is designed to search for voids and inhomogeneities inside the materials under testing with ultrasound. It is the most common device in the world for non-destructive testing of metal (and other materials with low attenuation of ultrasonic waves) products in production, as well as objects in operation.

Ultrasonic Flaw Detector NOVOTEST UD2301 is a powerful, ergonomic, portable device that has all the functions of a general industrial ultrasonic flaw detectors and can be used in laboratories and workshops, and is perfect for field use.

The main advantages of the Ultrasonic Flaw Detector NOVOTEST UD2301 are below:

MULTIFUNCTIONAL

The device has wide functionality:

– presentation of the signal like A-scan and B-scan, which allows the operator to select the desired operating mode in accordance with the task;

– the device has two independent gates, with the ability to evaluate parameters in different areas on the scan, also using the automatic defect alarm function the limits can be configured individually for each gate.

– for better signal processing, the device has functions of freezing and envelope, which allows the user to more accurately evaluate the received data.

DAC AND TVG FUNCTIONS

The device implements the Distance Amplitude Correction (DAC) and Time Varied Gain (TVG) functions, with the setting up to 16 points, which allows the operator to evaluate the equivalent reflector size at various depths.

DGS FUNCTION

Also in the device there are Distance Gain Size (equivalent) diagrams that allow user to build an amplitude curve from one standard reflector, as well as calculate the equivalent reflector size of tested discontinuities.

ARCHIVE

The device has an archive for storing measurements, settings for a specific object, settings of transducers to quickly switch settings when changing the testing object .

ANY DISPLAY ORIENTATION

A unique screen orientation function is implemented in the Ultrasonic Flaw Detector NOVOTEST UD2301, depending on the conditions under which the testing is performed, the screen orientation can be either vertical or horizontal. Also, the screen can be configured for both right-handed and left-handed people, i.e. the screen can be rotated 360°.

AUTONOMY

The device powered from three standard AA batteries, which makes the device completely independent of the stationary power source, the internal charger allows the battery to be charged from the standard USB 5V socket, with power bank the device can be used continuously for almost unlimited time.

DESIGN

The device has a transflective TFT display with a resolution of 480x320px, the enclosure is made in an ergonomic shape with a rubber bumper, which makes the device shockproof and resistant to falls. To connect the probes, standard connectors are used, which allows the operator to use any transducers without restrictions.

The device is supplied with PC software for uploading the measurement archive and processing the results.

- Superbright display with which it is comfortable to work outdoors on a sunny day;

- Frequency range from 0 to 10 MHz, with smooth adjustment;

- Display of a scale of scanning in microseconds and millimeters;

- Construction and processing A-scan and B-scan;

- The presence in the device of the operating mode of the DAC curves (construction of 16 points);

- Existence in the device of TVG mode (construction of 16 points);

- DGS function, with automatic calculation of the equivalent reflector size;

- Archive of measurements, settings, transducers with the ability to transfer data to a PC;

- Any side display orientation options that allow user to work in any position of the device;

- The device operates on standard AA batteries, as well as on conventional batteries, which makes them easy to replace;

- The NOVOTEST UD2301 flaw detector can be powered by a universal mobile battery (power bank) via a mini USB connector;

- Ergonomic shockproof case with protective rubber protectors;

- Light weight and compact size.

| Operating frequency range | from 1 to 10,0 MHz |

| Range of measured time intervals (duration of scanning) | from 6 to 1000 µs |

| Velocity range | 1000 – 9999 m / s |

| Error of measurement of time intervals | not exceed ± 0,025 µs |

| Maximum permissible error of measurement of the amplitudes of the signals at the receiver input in the range from 0 to 110 dB | not exceed ± 0,5 dB |

| Testing gain range | 125 dB |

| Averaging over the quantity of starts | from 1 to 16 |

| Range of variation of temporal sensitivity adjustment (TVG) | 40 dB |

| Number of control points TVG | 16 |

| Duration of the excitation pulse to the load | from 0,0 to 0,5 µs |

| Deviation of the amplitudes of input signals in the range from 10 to 100% of the screen height not more than | 1 dB |

| Setting a delay in the prism of the probe | from 0 to 15 µs |

| Detection of signals | positive half-wave, radio mode |

| Dimensions (W*H*L) | 80*162*38 mm |

| Weight, not more | 250 g (without batteries) |

- Couplant

- UT-probes

- Calibration blocks

- Ultrasonic flaw detector

- UT-probes – 2 pcs

- Cable Lemo-Lemo – 1 pc

- AA batteries – 3 pcs

- Charger

- USB cable for PC connection

- Operating manual

- Case

UT-Probes (Transducers)

We produce probes (transducers) of general type, and special-purpose, standard and custom: straight beam, angle beam, dual element, ground in and others.

All the transducers are designed for using with ultrasonic flaw detectors.

Connector type: Lemo 00 (other connectors – by request).

Contact dual-element transducers are designed for testing welded and brazed joints of the elements of metal structures, pipelines for detection the different kinds of defects (cracks, nonmetallic particles, pores, lack of fusion, scratches, surface cracks, etc.).

Straight beam contact transducers are designed to detect internal defects (pores, cracks, delamination and others), also they used for searching local thinning walls in metal structures and walls of the product, including the low-alloyed and austenitic steels products.

Transducer grounds are designed to detect internal defects of pipes and for searching local thinning walls of the pipes, including the low-alloyed and austenitic steels products.

- different kinds transducers for all tasks

- competitive price

| Model | Operating frequency, MHz | Angle, deg. | Comments |

Contact angle beam transducers | |||

| P121-2,5-40 | 2, 5 | 40 | Manufacturing under the order with any other specified parameters |

| P121-2,5-45 | 2, 5 | 45 | |

| P121-2,5-50 | 2, 5 | 50 | |

| P121-2,5-60 | 2, 5 | 60 | |

| P121-2,5-65 | 2, 5 | 65 | |

| P121-2,5-70 | 2, 5 | 70 | |

| P121-2,5-75 | 2, 5 | 75 | |

| P121-2,5-90 | 2, 5 | 90 | |

| P121-5-40 | 5 | 40 | |

| P121-5-45 | 5 | 45 | |

| P121-5-50 | 5 | 50 | |

| P121-5-60 | 5 | 60 | |

| P121-5-65 | 5 | 65 | |

| P121-5-70 | 5 | 70 | |

| P121-5-75 | 5 | 75 | |

| P121-5-90 | 5 | 90 | |

| Contact straight beam transducers | |||

| P111-2,5-К12 | 2,5 | 0 | Manufacturing under the order with any other specified parameters |

| P111-5-К6 | 5 | 0 | |

| P111-5-К12 | 5 | 0 | |

| P111-10-К10 | 10 | 0 | |

| P111-2,5-К20 | 2,5 | 0 | |

| P111-1,25-К20 | 1,25 | 0 | |

| Ground–in transducers | |||

| P121-2,5-40-ØХХХ | 2,5 | 40 | Manufacturing diameter of curvature under the order |

| P121-2,5-45-ØХХХ | 2,5 | 45 | |

| P121-2,5-50-ØХХХ | 2,5 | 50 | |

| P121-2,5-60-ØХХХ | 2,5 | 60 | |

| P121-2,5-65-ØХХХ | 2,5 | 65 | |

| P121-2,5-70-ØХХХ | 2,5 | 70 | |

| P121-2,5-75-ØХХХ | 2,5 | 75 | |

| P121-5-40-ØХХХ | 5 | 40 | |

| P121-5-45-ØХХХ | 5 | 45 | |

| P121-5-50-ØХХХ | 5 | 50 | |

| P121-5-60-ØХХХ | 5 | 60 | |

| P121-5-65-ØХХХ | 5 | 65 | |

| P121-5-70-ØХХХ | 5 | 70 | |

| P121-5-75-ØХХХ | 5 | 75 | |

| Dual element transducers | |||

| P112-2,5-12/2 | 2,5 | 0 | Manufacturing under the order with any other specified parameters |

| P112-2,5-20/2 | 2,5 | 0 | |

| P112-5-10-2 | 5 | 0 | |

| P112-5-3х4 | 5 | 0 | |

We can produce transducers for users requirements.

For any requirements (specifications, type of connector) of probe, please contact us before ordering.

Also, we produce Transmitter-Receiver-Longitudinal (TRL) angle probes or Ground-in dual element transducers.

- Transducer (probe)

- Package

EMAT Thickness Gauge NOVOTEST UT-3M-EMA

EMAT Thickness Gauge NOVOTEST UT-3M-EMA is a new development of the NOVOTEST company, which will allow our users to solve not only the standard tasks of testing the thickness of metal products, but also to carry out tests in cases where traditional methods, such as piezo-ultrasonic, laser-optical, X-ray, mechanical, etc. – not applicable.

Electromagnetic-acoustic (EMA) technology for measuring thickness is based on the excitation of ultrasonic waves in the material by the generator of the device’s probe, and fixing the path time of ultrasonic waves in the material.

So, the technology is similar to the most common piezo-ultrasonic method, however, the EMAT Thickness Gauge NOVOTEST UT-3M-EMA thickness gauge has several advantages:

CONTACTLESS MEASUREMENT

The electromagnetic-acoustic thickness gauge allows user to measure the thickness of metal products with one-way access without using couplant through a substantial gap (up to 6 mm). This significantly reduces the material- and laboriousness of the measurement process.

MEASUREMENT THROUGH PAINTED, OXIDIZED OR OILY SURFACES

EMA technology generates waves directly in the material (ferromagnetic and paramagnetic), thus allowing measurements to be carried out under a coating or with a poorly prepared surface, which may not be feasible with traditional methods.

HIGH TEMPERATURE PROBES

EMAT Thickness Gauge NOVOTEST UT-3M-EMA can be equipped with probes for operation on surfaces heated to a temperature of 600 °C, which makes this device the best, and in some cases, the only possible solution.

MEASUREMENT RANGE

A significant advantage over competitors is the range of measured thicknesses. The EMAT Thickness Gauge NOVOTEST UT-3M-EMA allows measuring walls from 0.5 mm to more than 200 mm, depending on the probe used.

THICKNESS GAUGE EXECUTION

EMAT Thickness Gauge NOVOTEST UT-3M-EMA is made in a durable and lightweight metal case. By special order, the thickness gauge can be made in dust and waterproof design (IP65). The thickness gauge is equipped with lithium-ion high-capacity batteries, which allowed for a long battery life. By special order, the battery capacity can be further increased, which will allow user to operate up to 30 hours from a single battery charge.

AUTOMATIC OPERATION MODE AND VARIOUS TYPES OF SIGNAL DISPLAYING

The EMAT Thickness Gauge NOVOTEST UT-3M-EMA implements a unique operating mode – the device automatically analyzes the measured signals, selects the required measurement method, adjusts the parameters of the receiving path and displays the measured thickness on the device’s screen. Even an unskilled user with this mode will be able to accurately and rapidly measure the thickness of various metal structures and products.

By default, the signal in the device is displayed like an A-scan, and the available operating modes allow the operator to evaluate the signals using different methods (PEAK-PEAK, FRONT, ECHO, ECHO-ECHO). Also the B-scan mode is implemented in this thickness gauge, which allows user to get the product profile like a graphical, convenient for perception. Using a specialized carriage for the probes, it becomes possible to scan extended objects and obtain a thickness profile.

Also, EMAT Thickness Gauge NOVOTEST UT-3M-EMA comes with special software for operate with the archive of the device, and the subsequent transfer of data for processing in convenient formats.

- A significant advantage in comparison with analogues is the unique automatic operation mode of the thickness gauge. The device automatically analyzes the measured signals, selects the required measurement method, adjusts the parameters of the receiving path and displays the measured thickness in large numbers on the display. Even an unprepared user in the automatic mode will be able to accurately and quickly measure the thickness of various metal structures and products.

- It is also necessary to pay attention to the fact that the device implements the B-scan mode, which allows user to get the product profile like a picture that is easy to read. Using a specialized carriage for the probe, it becomes possible to scan extended objects and obtain a thickness profile.

- In cases when it is necessary to sort the products with clearly defined thicknesses (min., max.), above which a decision is taken on the products is defective, a special control mode of the thickness gauge is used. The operator sets the minimum and maximum gates and watch a graphical representation on the display of the measured thickness, receives an alarm when the measured thickness goes beyond the gate and also can estimate corrosion damage as a percentage of the nominal thickness of the product.

- For expert testing, it is possible to carry out manual measurements using all known methods – using the autocorrelation function (ACF), measurement between two maximum signals in the gate, echo by zero crossing, echo echo passing through zero.

- To calibrate the device, there is a special auto calibration mode on a standard thickness sample.

| Measuring thicknesses range for steel, mm | 0.5…200.0 |

| Unit Type | mm |

| Discretization, mm | 0,01 |

| Type of ultrasonic wave | transverse |

| Manual gain range, dB | 100 |

| Ultrasound velocity adjustment range, m/s | 1000-9999 |

| Frequency averaging signal | 1-128 |

| Operating modes | A-scan B-scan Control mode Calibration mode |

| Measurement methods | Autocorrelation function (ACF) Echo Echo Echo (Dual Echo) Peak peak Front |

| Display | 3.5 inch 320 * 480 |

| Menu Language | Russian, English |

| Standard |

|

| Weight of the electronic unit, not more, kg | 0.5 |

| Dimensions (L x W x H) | 165x90x50mm |

| Power Supply | Built-in Li-ion Battery |

| Time of continuous work, not less than, h | 8 |

| Operating temperature range for the electronic unit, ° C | -20 to +50 |

- Different type of probes

- Calibration blocks

- Electronic unit

- Probe

- Cable (2 Lemo 00- 2 Lemo00)

- USB cable

- Charger

- Case

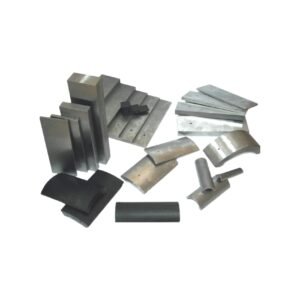

Calibration Blocks

Calibration blocks of enterprises with notches are used to configure the sensitivity and duration of scan of ultrasonic flaw detectors for testing of various products (mainly flat sheets and pipes).

Calibration blocks of enterprises with notches are used to configure the sensitivity and duration of scan of ultrasonic flaw detectors for testing of various products (mainly flat sheets and pipes).

Calibration blocks of enterprises with notches (corner reflectors) are made of the same material as the tested object, wherein the geometry (thickness and surface radius of standard sample) has the same characteristics as tested item.

- High quality and accuracy

- Competitive price

There are 4 kinds of calibration blocks:

- Flat calibration block with a notch;

- Сalibration block of pipe with a notch for testing the longitudinal weld;

- Сalibration block of pipe with a notch for testing the transverse weld;

- Сalibration block of pipe with a notch for testing the piping bend.

As a rule, calibration blocks are produced in accordance with the client’s specific normative document which governs:

- Dimensions of the calibration block

- Dimensions (width and depth) of notches

- Location of notches of the sample

- Number of notches

We produce calibration blocks under the technical projects or drawings of customer.

- Calibration block

- Certificate

Thickness Gauge Calibration Blocks

Set of KUSOT-180 ultrasonic thickness calibration blocks is intended for examination and for initial inspection at manufacturing of ultrasonic contact thickness gauges.

KUSOT-180 сalibration blocks are also used for verification, calibration and metrological certification of ultrasonic thickness gauges.

KUSOT-180 сalibration blocks are used in the following ranges:

- 0,2-300 mm on steel

- 1-300 mm on duralumin

- 1-100 mm on brass

The kit consists of the thickness samples, combined in sets and packed in a case.

Step-calibration blocks (Step wedge calibration blocks) are used for adjustment and calibration of ultrasonic thickness gauges.

Linear dimensions of Step wedge calibration blocks are individually available by a customer request and according to the acting regulatory and technical documentation.

- High quality of the materials

- High precision blocks to a tolerance of ±1%

The blocks can be supplied as a complete set or separately.

| No. of set | Name of set | Material | Nominal thickness values |

| No.1 | Standard set of plane-parallel thickness blocks | Alloy D16 | 1; 2; 3; 4; 5; 6; 7; 8; 9; 10; 12; 15; 18; 20; 25; 30; 35; 40; 45; 50; 75; 90; 100. |

| No.2 | Standard set of plane-parallel thickness blocks | Steel 40H13 | 1; 2; 3; 4; 5; 6; 7; 8; 9; 10; 12; 15; 18; 20; 25; 30; 35; 40; 45; 50; 75; 90; 100. |

| No.3 | Standard set of plane-parallel thickness blocks | Steel 40H13 Alloy D16 | 200; 300; 200; 300. |

Our company can produce both standard KUSOT kits and samples of the thickness of any other values of any required materials.

- Blocks

- Calibration certificate

- Case or package