Gauges

FLG

The dial level indicator has been designed for the level measurement of liquids in small and high tanks. Its operation is based on a clock gears movement of highest precision that assure a local indication with high accuracy and repeatability.

DIAL LEVEL INDICATOR

Two mechanisms have been planned in order to have two reading scale with single or double pointer. The instrument doesn’t need any electrical supply. The main characteristics are the reliability and the strength.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

H

For periodically checking the accuracy of other service gauges or pressure operated instruments and for precision measures of pressure.

TEST AND PRECISION PRESSURE GAUGE

Besides the construction accuracy, the easy reading is the basic characteristic of instruments Series H assured by mirror ring, subdivisions of graduation, dial color and pointer design.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | – Threaded G 1/2 A UNI/ISO 228/I. – Flanged 40 mm diam. (shipped with locking vice). Max 160 bar |

| Process Temperature | |

| Accuracy Class | Series 7H: 0.3%FS at 20°C Series 8H: 0.25%FS at 20°C Series 9H: 0.2%FS at 20°C |

| Solution |

MLG

A permanent magnet incorporated in the float actuates the sensing elements mounted in the special waterproof case, causing them to rotate 180°.

MAGNETIC LEVEL INDICATOR

These elements, which are treated with special paints of contrasting color on the two faces, show the red color faces when the level increases (float going up) and the white faces when the level decreases (float going down), thus showing very clearly the position of the float and hence the liquids’ level.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | Flanged from 1 1/2″ (JIS, UNI, ANSI) Socket welded from 1 1/2″ |

| Process Temperature | |

| Accuracy Class | |

| Solution |

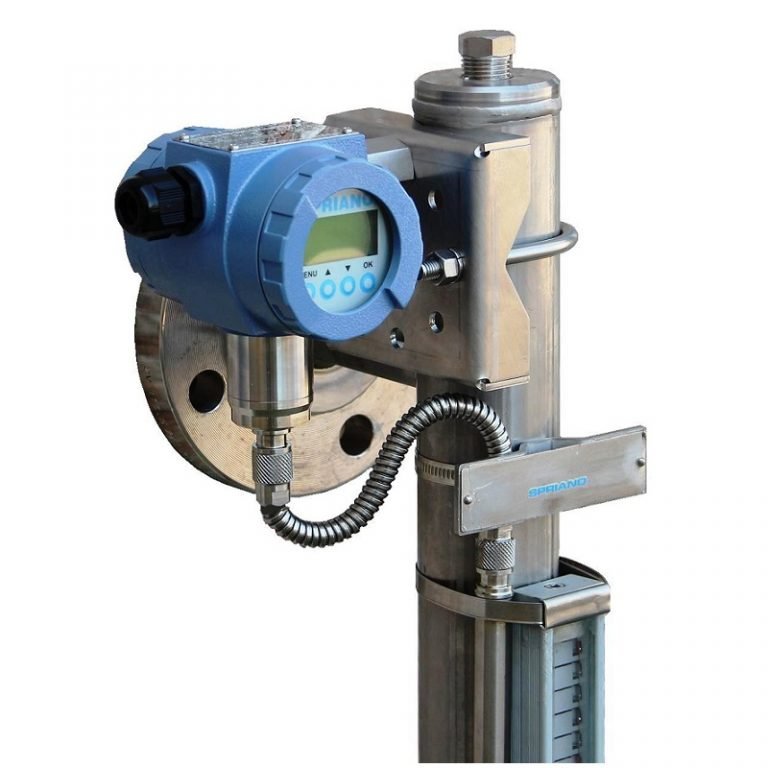

MLTG

MLTG series SMART visual reed transmitters are microprocessor based instruments that combine the 4-20mA+ HART® signal advantages (4-20mA) together with the convenience of local visualization of measurement by means of graduated scale.

SMART VISUAL LEVEL TRANSMITTER

They can be remotely configured by a universal hand held terminal (HHT) or by a PC with a dedicated interface. Moreover, it is possible to locally configure the instruments by means of 4 pushbuttons and to display the data on the wide LCD display or on the local graduated scale.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | Flanged from 1 1/2″ (JIS, UNI, ANSI) Socket welded from 1 1/2″ |

| Process Temperature | |

| Accuracy Class | |

| Solution |

MN04

MN04 series pressure gauges are tools combined with a separation membrane which, undergoing the pressure of the process fluid, activate the movement.

DIAPHRAGM PRESSURE GAUGE

This type of instrument can detect the pressure of highly viscous or crystallizable or solidifiable fluids.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | From 0…16 to 0…400 bar or equivalent other units of pressure or vacuum ranges |

| Process Connection | AISI 316 L stainless steel, Thread size for lower or back mounting: 1/2” BSP or NPT |

| Process Temperature | -20÷+100°C std -20÷+150°C w. special gaskets -20÷+100°C PTFE coating |

| Accuracy Class | |

| Solution |

MN07

MN07 gauges, are accurate instrument suitable to satisfy the hardness working conditions and the most severe requirements of the various industrial sectors for which have been designed.

CAPSULE GAUGE

The capsule can be made in Stainless steel, brass movement, AISI 316L St. St. pressure connection (NS 100 and 150) or Copper Beryllium capsule, Brass movement, Brass pressure connection (NS 63 e 100).

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | From 0…6 to 0…400 bar or equivalent other units of pressure or vacuum ranges |

| Process Connection | AISI 316 L stainless steel, Thread size for lower or back mounting: 1/2” BSP or NPT |

| Process Temperature | |

| Accuracy Class | |

| Solution |

MN11

MN11 gauges, are accurate instrument suitable to satisfy the hardness working conditions and the most severe requirements of the various industrial sectors for which has been designed.

BOURDON PRESSURE GAUGE

MN11 gauges, are accurate instrument suitable to satisfy the hardness working conditions and the most severe requirements of the various industrial sectors for which has been designed.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | From 0…0,6 to 0…1000 bar or equivalent other units of pressure or vacuum ranges |

| Process Connection | AISI 316 L stainless steel, Thread size for lower or back mounting: 1/2” BSP or NPT |

| Process Temperature | -30 ÷ +250 °C dry execution +10 ÷ +80 °C glycerine filled -30 ÷ +120 °C oil filled |

| Accuracy Class | Class 1 (1% FS) for DN100 e DN150 Class 1.6 (1.6% FS) for DN63 |

| Solution |

RLG

Reflex indicators display the fluid level through a transparent surface being part of a column that is connected to the vessel by on-off cock gauges.

REFLEX LEVEL INDICATOR

The measuring part is composed of one or more elements from prismatic borosilicate glass (crystal) which trigger the reflection or non-reflection of the environmental light depending on whether the inner surface comes or does not come into contact with the fluid or with the gas (vapor). The crystal is tightened to the inside of a steel box by means of bolts. Its sturdy construction and its good visibility, without using dedicated illuminators, make it ideal for use in heavy-duty applications with pressure up to 400 bars and temperature up to 427° C.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SGD11

For various types of applications. Differential pressure measurement with a high differential pressure overload and/or high working pressures (static pressures), also in aggressive ambient for gaseous, liquid, viscous and aggressive media.

DIFFERENTIAL PRESSURE GAUGE

Monitoring and control of pumps filter monitoring level measurement in closed tanks.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SGD14

This gauge is particularly recommended for application with gases, where tube spring failure can instantly multiply internal pressure.

SOLID FRONT TUBE SPRING PRESSURE GAUGE

The blow-out back is constructed to vent such pressure while the solid front between tube spring and dial prevents forward pressure release, leaving the laminated safety glass intact. With this gauge the safety of operator is increased.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

TLG

This type of indicators display the level of the fluid through a transparent surface, being part of a column that is connected to the vessel by on-off cock gauges. They are composed of one or more opposed pairs from smooth borosilicate glass (crystal) that are tightened inside a steel box.

TRANSPARENT LEVEL INDICATOR

The level reading is based on a different transparency of the fluid and the gas or vapor. In heavy-duty applications, the glass is protected by means of a mica shield, which however reduces the reading transparency. To remedy this phenomenon, special illuminators are used which exploit the total refraction / reflection effect in the fluid / gas or vapor separation surface. Reflection indicators are successfully used up to 250 bars and with temperatures up to 538° C.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

XTB

To these industrial type bimetal thermometers, with a cylindrical spiral sensing element, are peculiar characteristics, solidity , simplicity and the shape follow UNI and other international standards.

BIMETALLIC THERMOMETER

Petrochemical plants, dyeing and food industries are the more common application. They are two basics models: back stem and adjustable stem.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

XTG

Gas filled thermometers cover a wide temperature range (from -200 °C up to 700 °C).

GAS FILLED THERMOMETER

Their construction can grant full protection of personnel and process from accidental contamination, as the filling gas is Nontoxic, suitable in the food, pharmaceutical, chemical and petrochemical industries.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |