Pneumatics

65L

The transmitter series 65L measures liquid levels, density and interface levels in closed or open vessels.

INDICATING LEVEL CONTROLLER

It converts buoyant force exerted by a displacer immersed in a liquid to a proportional pneumatic signal thanks to a mechanical forces transmission device.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

FR10

The air filter regulator FR10 is specially designed for feed, with clean air and controlled pressure, all the measuring and control instrumentation, automatic machines and any type of pneumatic device.

REGULATOR, FILTER-MINITUARIZED

The high precision of control and its constructive characteristics make it particularly reliable even in environmental heavy conditions.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

FR20

The air filter regulator FR20 is specially designed for feed, with clean air and controlled pressure, all the measuring and control instrumentation, automatic machines and any type of pneumatic device.

FILTER-REGULATOR FOR INSTRUMENTS

The high precision of control and its constructive characteristics make it particularly reliable even in environmental heavy conditions.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

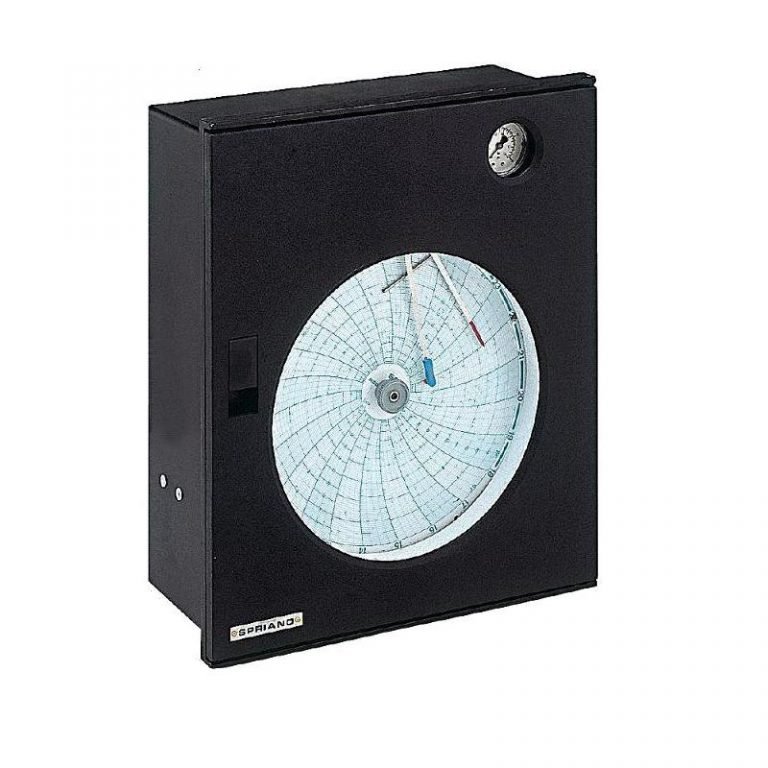

RNG

The circular chart recorders Series RNG with models 150 and 450 are suitable to record physical variables which temperature and pressure of liquids, gaseous or vaporous media in the industrial process plants.

CIRCULAR RECORDER

These series are mechanic continual trace recorders The system of writing is made by cartridge with fiber pen. Series allow the simultaneous registration up to three variables of daily or weekly processes (24 hours std).

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | Input signal (Pressure): -1…0 bar a 0…1000 bar. Input signal (Temperature): 0…25 °C a 0…500 °C. |

| Process Connection | Air supply and output: 1/4″ NPT with fitting for 4/6 mm pipe size. |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SEX11A

P to I converters SEX11A Series are designed to interface pneumatic 3÷15psi / 0.2÷1bar signals to controls systems, data loggers and other data acquisition systems.

PRESSURE TO CURRENT CONVERTER

P to I converters SEX11A Series are designed to interface pneumatic 3÷15psi / 0.2÷1bar signals to controls systems, data loggers and other data acquisition systems.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | Input signal: 20-100kPa (0,2-1bar), or 3-15PSI. Output signal: 4-20mA, 2 wires. |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SEX26

The positioner compares the electric or pneumatic input signal (4-20 mA, or 3-15psi) with the actuator’s position, generating a pneumatic output signal for proportional control actuator.

PNEUMATIC AND ELECTROPNEUMATIC POSITIONER

The positioner compares the output signal from a controller with the position feedback, and varies a pneumatic output signal to the actuator accordingly. The actuator position is therefore guaranteed for any controller output signal and the effects of varying differential pressure.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | Input: 3÷15Psi (0,2÷1bar) o 4÷20mA. Output: 0÷100% of the supply air pressure. |

| Process Connection | Pneumatic connections: 1/4″ NPT. Electric connections: Cable gland PG9. |

| Process Temperature | |

| Accuracy Class | |

| Solution |

PNEUMATIC AND ELECTROPNEUMATIC POSITIONER FOR ROTARY VALVES

The positioner operates on the force balance principle by comparing the standard signal transmitted from a pneumatic or an electronic controller device and the angular rotation of the stem, and conveys a positioning amplified pressure to the valve actuator. & double-acting Positioner, input signal.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | Input: 3÷15Psi (0,2÷1bar) o 4÷20mA. Output: 0÷100% of the supply air pressure. |

| Process Connection | Pneumatic connections: 1/4″ NPT. Electric connections: Cable gland PG9. |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SEX71

SEX71 I/P converters are based on a force balanced system with electronic feedback

CURRENT TO PRESSURE CONVERTER

SEX71 I/P converters are based on a force balanced system with electronic feedback: measuring the output signal, by means of a piezoelectric sensor, and computing it with dedicated SMT electronics, a reliable and high performing instrument is obtained.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | Input signal: 4-20mA, 2 wires. Output signal: 20-100kPa (0,2-1bar), or 3-15PSI. |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SG6100

The instrument senses the temperature, pressure or level of the measured medium directly, displays the operating value, compares the measured variable with the set point and puts out a pneumatic standard signal of 0,2 to 1bar or 3 to 15psi.

PNEUMATIC INDICATING CONTROLLERS AND TRANSMITTER

This output pressure actuates final control element, the pneumatic valve. Four control forms are available: T(ON-OFF), Proportional, Proportional + Integral, Proportional + Integral + Derivative. The units could be also used for remote control of process operations as pneumatic transmitter (output 0,2÷1bar or 3÷15psi) or receiver controller (input 0,2÷1bar, 3÷15psi).

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | Air supply and output: 1/4″ NPT with fitting for 4/6 mm pipe size. |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SG65

For the control of temperature, pressure and level, in industrial or process plants. The indicating controller is used for control of liquid, gaseous or vaporous media.

PNEUMATIC INDICATING CONTROLLER AND TRANSMITTER

The instrument senses the temperature, pressure or level of the measured medium directly, displays the operating value, compares the measured variable with the set point and puts out a pneumatic standard signal of 0,2 to 1bar or 3 to 15psi. This output pressure actuates final control element, the pneumatic valve. Four control forms are available: ON-OFF, Proportional, Proportional + Integral, Proportional + Integral + Derivative. The units could be also used for remote control of process operations as pneumatic transmitter or receiver controller.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | Air supply and output: 1/4″ NPT with fitting for 4/6 mm pipe size. |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SG74

The SG74 works on the force balance principle and consists of two main units: The measuring unit which detects the differential pressure variation and consists of two forged bodies and a bellows.

PNEUMATIC DIFFERENTIAL PRESSURE TRANSMITTER

The transmission unit converts the differential force applied to the measuring element into a proportional output pneumatic signal. The output pressure, generated by a flapper nozzle relay, feeds the feedback bellows with a rising pressure until the balance between bellows force and measuring element is reached. The whole transmission unit is contained within a water-resistant housing.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SG75

The SG75 works on the force balance principle and consists of two main units: The measuring unit which detects the differential pressure variation and consists of two forged bodies and a measuring capsule.

PNEUMATIC DIFFERENTIAL PRESSURE TRANSMITTER

The transmission unit converts the differential force applied to the measuring element into a proportional output pneumatic signal. The output pressure, generated by a flapper nozzle relay, feeds the feedback bellows with a rising pressure until the balance between bellows force and measuring element is reached. The whole transmission unit is contained within a water-resistant housing.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SG76

The SG76 works on the force balance principle and consists of two main units: The measuring unit which detects the differential pressure variation and consists of two forged bodies and a measuring capsule.

PNEUMATIC DIFFERENTIAL PRESSURE TRANSMITTER

The transmission unit converts the differential force applied to the measuring element into a proportional output pneumatic signal. The output pressure, generated by a flapper nozzle relay, feeds the feedback bellows with a rising pressure until the balance between bellows force and measuring element is reached. The whole transmission unit is contained within a water-resistant housing.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SG77

The SG77 works on the force balance principle and consists of two main units: The measuring unit which detects the differential pressure variation and consists of two forged bodies and a bellows.

PNEUMATIC RELATIVE PRESSURE TRANSMITTER

The transmission unit converts the differential force applied to the measuring element into a proportional output pneumatic signal. The output pressure, generated by a flapper nozzle relay, feeds the feedback bellows with a rising pressure until the balance between bellows force and measuring element is reached. The whole transmission unit is contained within a water-resistant housing.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |

SS200

Manual loading station is used for the remote positioning of air control valves and other pneumatic control equipment.

CONTROL PANNEL IN MANUAL STATION

Manual loading station is used for the remote positioning of air control valves and other pneumatic control equipment.

| Application Cases | |

|---|---|

| Principle | |

| Measuring Range | |

| Process Connection | |

| Process Temperature | |

| Accuracy Class | |

| Solution |